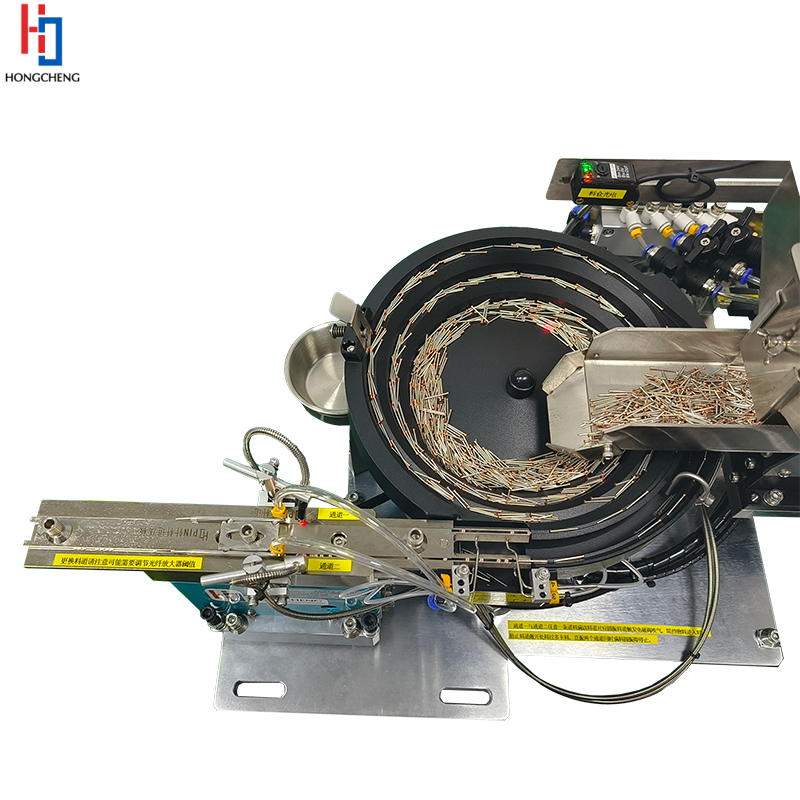

What is aluminum vibratory bowl feeder? In fact, it is a very common automatic feeding equipment in automated production lines. The core structure of vibratory bowl feeder is a bowl-shaped plate made of aluminum. With the electromagnetic vibration device at the bottom, various small parts are arranged and output in a set direction and in an orderly manner through continuous micro-vibration. Many people may think it is a magic trick when they see it for the first time, because those scattered parts automatically circle, queue up, and walk out of the bowl. The whole process is quiet and efficient, which is very magical.

The biggest features of aluminum vibratory bowl feeder are "stability" and "customization". Because it is made of a whole piece of aluminum, it is not only strong, wear-resistant and durable, but also the inside of vibratory bowl feeder can be carved into complex guide rail channels according to different part structures. This customization capability allows it to handle parts of various shapes and sizes, such as electronic components, screws and nuts, hardware, medical plastic parts, etc., especially in situations where precise positioning is required and scratches are not allowed. Compared with plastic bowls, aluminum bowls have a longer life, are more resistant to changes in ambient temperature, are more stable during operation, and basically do not need to be adjusted.

Our factory specializes in the production of core components in various types of automation equipment, including high-precision aluminum vibratory bowl feeder. Each aluminum bowl is carefully carved by us using five-axis CNC equipment. From design, drawing, programming, processing to grinding and polishing, each link has strict standards. We can design the bowl structure according to the customer's material samples and feeding requirements to ensure feeding efficiency and stability. In addition, we have a complete set of aluminum bowl surface treatment processes, including anodizing, hard treatment, anti-corrosion coating, etc., so that the equipment can run longer and more safely in actual working conditions.

In addition to the equipment itself, we also attach great importance to service. Customers can send samples directly, and we provide free preliminary evaluation; if on-site testing is required, we welcome customers to come to the factory for debugging together; if problems are encountered during subsequent installation and use, we provide remote video guidance and technical Q&A. If the customer has plans for mass production, we can also provide multiple sets of parallel solutions to make the entire production line faster and more stable.

Now more and more companies are beginning to pay attention to production line automation, and the feeding system is a very important part of it. Choosing a suitable aluminum vibratory bowl feeder can not only improve production efficiency, but also reduce manual intervention and error rate. Our customers are in many industries such as electronics, automobiles, medical, and daily chemicals. Many of them are old customers who have cooperated for many years and come to us for design with new projects every year.

If you are also looking for an efficient, stable and durable feeding system, you may want to take a look at our aluminum vibratory bowl feeder. You are also welcome to send the materials to try it out. It may be a good helper for your production line upgrade.