In the candy packaging workshop, two feeders are working. The chocolate beans on the aluminum vibratory bowl feeder on the left roll in an orderly manner, and the gummy candy in the vibratory bowl feeder on the right runs smoothly. In the processing of food-grade components, there is no absolute difference between the two machines. The key depends on the specific application scenarios.

Aluminum vibratory bowl feeder can be used when hygiene requirements are more stringent. The surface of food-grade aluminum alloy is specially anodized to form a protective layer, which meets FDA certification standards. This surface does not adsorb impurities, it is particularly convenient to clean and disinfect, and it will not adsorb food residues, reducing the risk of cross-contamination. When handling nuts, candy and other foods of a certain weight, the wear-resistant advantages of aluminum can be reflected. It can withstand long-term high-intensity use, and the aluminum vibratory bowl feeder will not show significant wear and tear on the plate surface for three consecutive years.

In some special scenarios, only the vibrating bowl feeder can be used. For acidic foods or salted products, corrosion-resistant engineering plastics are a good choice. Lightweight puffed food is easier to flow on plastic trays, and some customers especially like the visual effect of transparent plastic. The transparent plastic material can also facilitate operators to observe the flow of materials and find and solve problems in time. The electrostatic control technology of the new food-grade plastics we produce is also getting better and better, and now potato chips can be delivered stably.

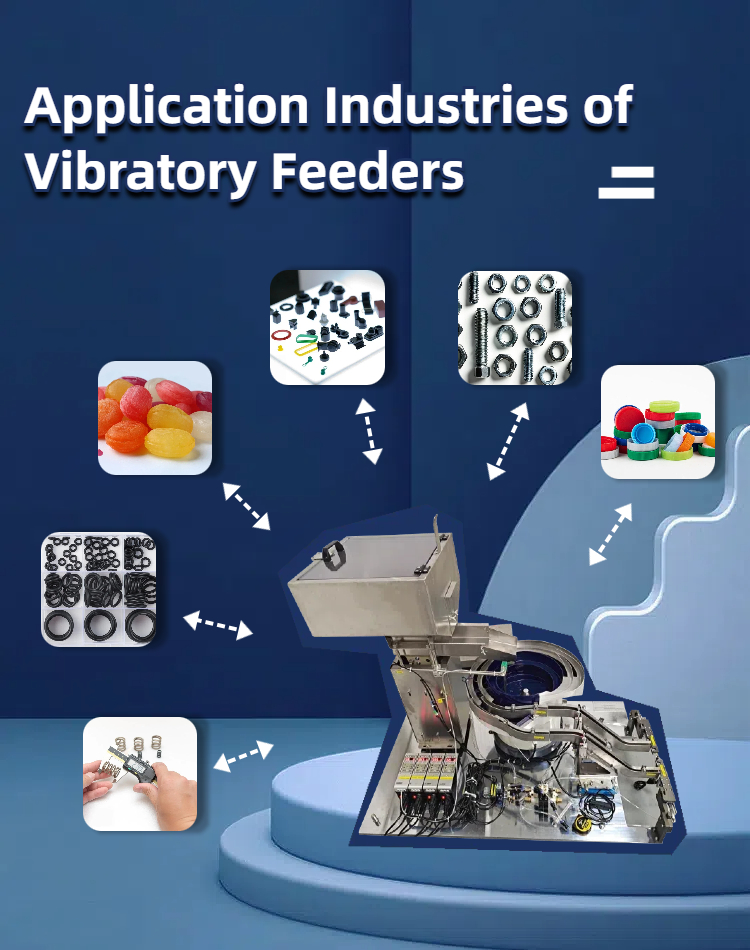

Shenzhen Hongcheng Automation Equipment Co., Ltd. It is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for bowl feeder systems. We not only provide standardized aluminum vibratory bowl feeder and vibratory bowl feeder, whether it is aluminum or plastic, we can customize exclusive solutions for customers. The aluminum plate can be equipped with an anti-static coating, and the plastic model can also be modified according to customer requirements. Whether you need aluminum to be strong and durable, or plastic to be lightweight and corrosion-resistant, we can provide the most suitable choice.

From the entry of raw materials into the factory to the delivery of finished products, we strictly implement the quality management system to ensure that each equipment meets the highest standards. Whether it is nut fried goods or snack foods, we can provide matching feeding solutions to keep your production line running efficiently. We also have a perfect after-sales service system and excellent after-sales service personnel. If you are interested in the customized service of our bowl feeder, please feel free to contact us!