In the automated production line, many people will ask a question: What is the difference between Centrifugal Feeder and Vibratory Bowl Feeder? Both devices seem to be able to arrange the parts neatly and send them out, but their working methods are actually quite different.

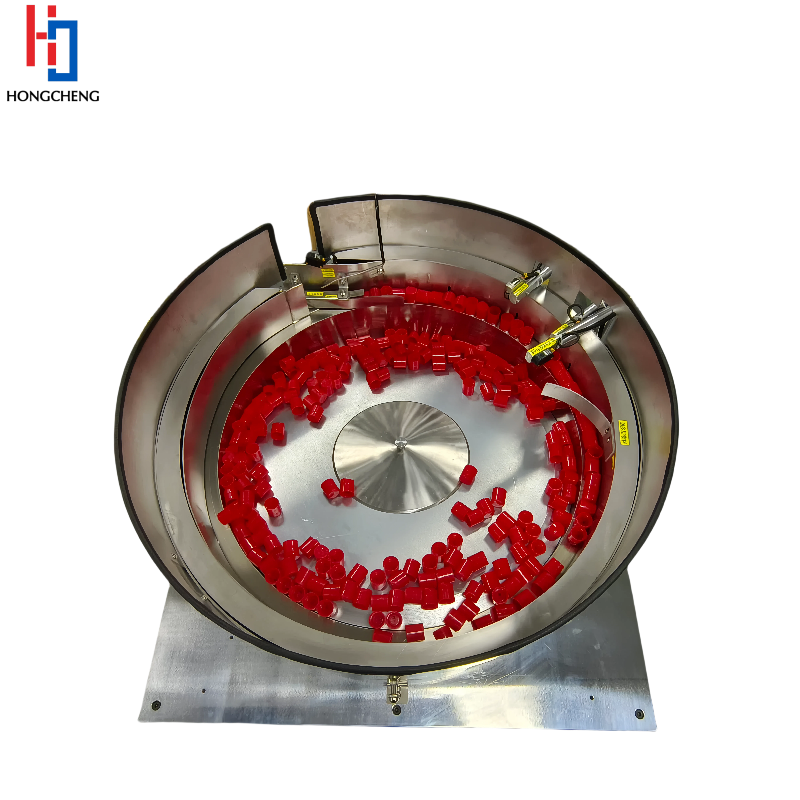

Simply put, Centrifugal Feeder relies on "swinging" and Vibratory Bowl Feeder relies on "vibration". Centrifugal Feeder uses a high-speed rotating disc to throw the parts to the outer guide rail, and uses centrifugal force to quickly output the parts in an orderly manner. It is fast and efficient, and is particularly suitable for those regular, light and small parts that are not easy to get stuck, such as bottle caps, lids, plastic rings, etc. Vibratory Bowl Feeder is a vibrating bowl with a spiral track, and the parts gradually climb to the exit during vibration. Vibratory Bowl Feeder has a wider range of applications. Even if the parts have small grooves and complex shapes, they can be arranged in a directional manner through vibration and track design.

Hongcheng is a factory specializing in the production of automated feeding equipment. We can produce both Centrifugal Feeder and Vibratory Bowl Feeder. Our Centrifugal Feeder uses a precision-machined aluminum alloy turntable, which has stable operation, fast speed and low noise, and is very suitable for high-speed packaging lines, filling lines, assembly lines and other needs. What's even better is that the Centrifugal Feeder produced by Hongcheng can be easily matched with visual systems, manipulators, conveyor lines, etc. to achieve automated continuous operation.

The Vibratory Bowl Feeder we produce is also very powerful. From the structural design of the Vibratory Bowl Feeder to the vibration adjustment, we have made a lot of optimizations to ensure that parts of different shapes can be stably fed. For those small parts with different sizes, easy to spin or roll, we can perform special treatments through track customization, baffle adjustment, outlet feeding, etc. Each feeder is tested for a long time before leaving the factory to ensure that customers can use it directly after receiving it, without debugging and zero worries.

Some customers asked us if we can do non-standard customization? The answer is of course yes! We support customization according to customer product characteristics and production rhythm, including discharge direction, track width, drive mode, voltage, control mode, etc. Whether you are doing daily chemicals, medicine, electronics or hardware accessories, we can provide suitable feeding solutions according to your actual situation.

In terms of factories, we have an independent R&D team and a complete production workshop. All parts are completed internally from processing to assembly to ensure stable quality. We are also equipped with advanced processing equipment, such as CNC machining centers, laser cutting machines, high-speed punching machines, etc. Each device has been precision-tested to truly strictly control every detail. Not only do domestic customers like our equipment, our feeders are also exported to Southeast Asia, Europe and other countries, serving global customers. If you happen to need a feeder, welcome to talk to us, maybe we can help you solve a lot of "little troubles"!