Hearing the word "centrifuge tube", some people may immediately think of the glass tubes, small bottles, and high-speed rotating instruments in the laboratory. Yes, the centrifuge tube is used to hold samples. It plays a very important role in the laboratory, especially when separating liquids or particles of different densities. It is simply a magical operation. With a rapid rotation, blood, cells, microorganisms, liquid medicine and other components are clearly distinguished.

But today we are not talking about the laboratory, but taking advantage of this "centrifuge" topic, I would like to share with you the star equipment in our Hongcheng factory that also "relies on spinning" - Centrifugal Feeder.

Centrifugal Feeder is a bit similar to the principle of centrifuge tubes. They all use the centrifugal force generated by high-speed rotation, but they are not used for separation, but for loading. What does it mean? Imagine that a pile of parts and accessories are piled together on the production line. Manual sorting is slow, manual loading is tiring, and it may be wrong. Centrifugal Feeder is like an automatic drying and queuing machine, which "throws" the scattered parts into a neat formation and then accurately sends them to the next process.

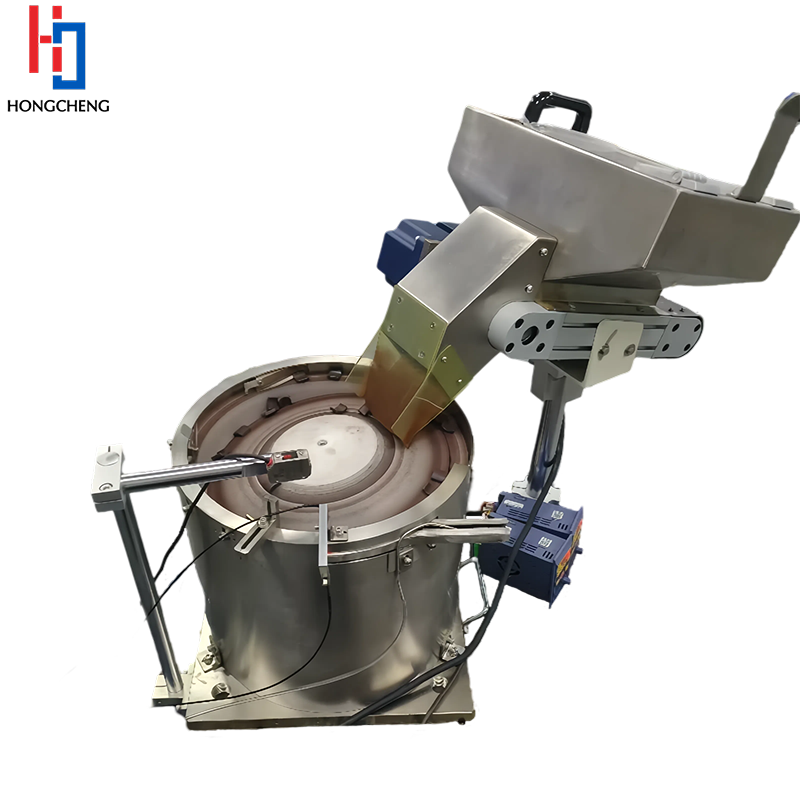

What does Centrifugal Feeder look like? The appearance looks like a turntable + material channel combination, and the internal fine design allows parts of different sizes and shapes to automatically return to their positions during rotation. Centrifugal Feeder has many advantages, such as fast loading speed, no damage to the workpiece, almost maintenance-free, and automatic rejection of unqualified products. A customer commented, "After using the Centrifugal Feeder produced by Hongcheng, the whole workshop is quiet, the workers are relaxed, and the efficiency is high." Hongcheng has a professional design team, which not only has a complete range of standard models, but also supports personalized customization.

What material, shape, weight, and speed of your product are, we can make the most suitable solution according to the actual working conditions. The production equipment is advanced and the quality inspection process is strict. Every Centrifugal Feeder must pass the simulation test before leaving the factory to ensure that it is a "production tool" that can be started directly in your hands. Some customers make electrical switch parts. They used traditional vibration plates, which often jammed and were unstable during the loading process. After switching to the Centrifugal Feeder designed by us, the daily output increased by nearly 40%, and the scrap rate was significantly reduced. There are also customers who make medical plastic parts, and their requirements are very high. We have made anti-static design for Centrifugal Feeder and installed intelligent visual recognition modules to achieve "zero error" for their intelligent production line.

Interestingly, many customers were unfamiliar with the name Centrifugal Feeder at first, and they refused to change to other ones after using it. Because Centrifugal Feeder is not just a machine, but also a solution to help companies reduce costs and increase efficiency.

So, next time you hear the word "centrifuge", you don't have to think only of laboratory tubes, you can also think of our little expert who is "spinning circles" quietly and efficiently. If you also want to change your production line to a "feeding butler", you might as well take a look at our HONGCHENG Centrifugal Feeder, which may just suit your taste.