The material selection of the bowl feeder affects the performance and service life of the equipment. Plastic and aluminum bowl feeder have different characteristics and are suitable for different industrial scenarios. This article mainly explains the difference between these two machines and helps everyone choose a suitable feeding plan.

The small density of aluminum makes the aluminum bowl feeder lighter in weight. Aluminum bowl feeder will be selected for most application scenarios. The aluminum alloy material has good corrosion resistance, and the surface is more wear-resistant after anodizing treatment. Aluminum bowl feeder has low inertia when running, and the start-stop response is very fast. It is very suitable in scenarios where frequent movement is required or the weight of the equipment itself is required. Aluminum bowl feederis also a suitable choice for the transportation of light-weight materials such as electronic components and small plastic parts.

The pan body made of food-grade plastic meets hygiene standards and is suitable for the food and pharmaceutical industries. The plastic does not produce static electricity, and it will not damage sensitive parts when handling electronic components. The weight is more than 30% lighter than aluminum, making it more convenient to install and carry.

The aluminum disc body can be washed with ordinary detergent, and it can be sterilized with high temperature resistance. Although the plastic disc body is not high temperature resistant, the surface is smooth and does not store impurities, and it can be rinsed with water. If there are occasions where anti-static requirements are required, special coatings can be added to the plastic tray to prevent the material from sticking.

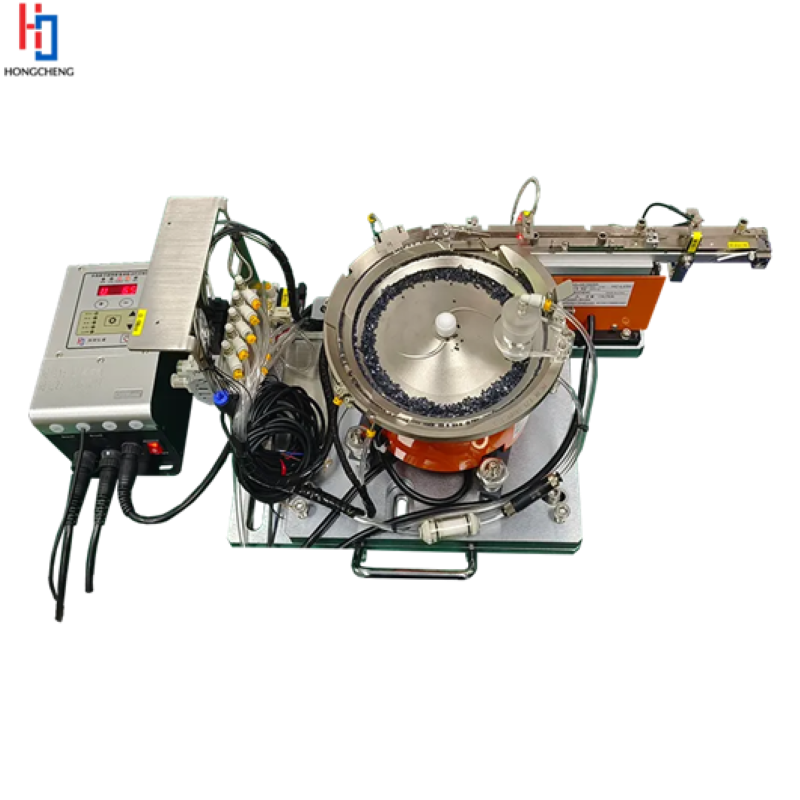

Our company provides both plastic and aluminum bowl feeder. Our aluminum products have been precision machined and tested to ensure the smooth operation of the machine. The plastic series is also guaranteed, safe and non-toxic.

Shenzhen Hongcheng Automation Equipment Co., Ltd. has advanced production equipment and a professional technical team, which can customize various types of aluminum bowl feeder according to the specific needs of customers. We can provide solutions for simple material transportation or complex material orientation arrangement.

The feeders we produce are efficient and stable, with low operating noise and easy operation, and are widely used in many industries such as electronics, hardware, food, medicine, etc. In addition, we continue to invest in research and development to improve product performance to meet increasingly diverse market needs and create greater value for our customers. We have a perfect after-sales service system and excellent after-sales service personnel. Committed to providing customers with efficient, reliable and customized automation solutions. If you are interested in our aluminum bowl feeder, please feel free to contact us!