On the production line, Vibratory Bowl Feeders and Small Conveyors are both common material handling equipment, but they are very different in terms of function and application scenarios. Understand the differences and choose the right feeding solution for your production line.

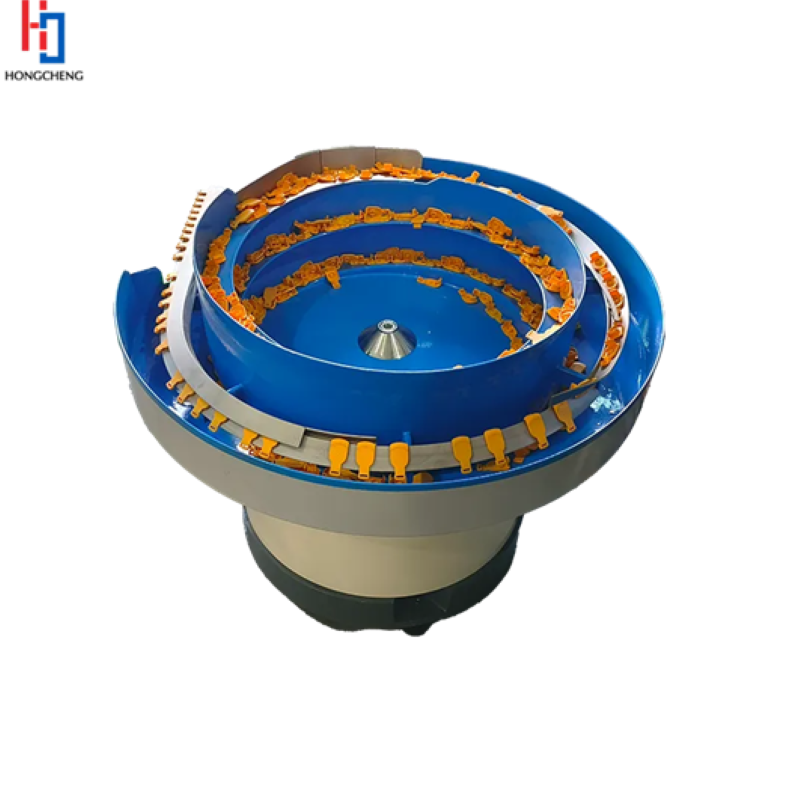

The main functions of the vibratory bowl feeder are sorting and orientation. The high-frequency vibration allows the parts to be arranged in an orderly manner on the disc surface, making it suitable for handling small parts with complex shapes that require a specified orientation. Electronic components, hardware, medical devices and other products need to be positioned during production, then the vibratory bowl feeder is very suitable. Small conveyors are more suitable for straight-line transportation of materials, which can transfer products from one station to the next station stably and continuously, and are suitable for regular items that have already been oriented.

The vibratory bowl feeder can process more parts in a given time. A vibratory bowl feeder sorts and conveys thousands of small components per minute, much faster than a normal conveyor. However, conveyors have more advantages in long-distance transportation, which can easily convey materials several meters or even farther; whether they are granules, lumps or finished items, they can be conveyed through small conveyors.

Conveyors usually require a larger area, because the conveyor occupies a larger area when transporting items far away. The disc body of the vibratory bowl feeder is small, and the entire machine occupies a small area. For workshops with limited space, this distinction may be the key to choice.

Shenzhen Hongcheng Automation Equipment Co., Ltd. It is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for feeder systems. We provide customized solutions. The vibratory bowl feeder we produce can adjust the track design according to the size of the parts, and even special-shaped parts can be transported in a directional manner. And the disc material can also be customized according to your needs, you can choose stainless steel, aluminum alloy or special coating treatment to meet the needs of different industries.

We have a professional design team and advanced production equipment. From the selection of raw materials to the testing of finished products, every link is strictly tested to ensure product quality and performance. Our logistics is very fast, making the products delivered on time. We will continue to invest in research and development to ensure that our products are technologically advanced and meet the latest industry needs. If you have any questions, please feel free to contact us!