The style and working principle of the vibratory bowl feeder selected according to the different needs of the industry will be different. In electronic components, pharmaceutical capsules, food and other industries, different industries will select the material, structure design and functional configuration of the vibratory bowl feeder according to the production requirements.

The high precision vibratory bowl feeder for parts in the electronics manufacturing industry pays great attention to anti-static functions. The disc body is generally made of special aluminum alloy, and the surface is electrically conductive and oxidized to reduce the adsorption of tiny components due to static electricity. The track design requirements are also very high to ensure that the SMD components can be accurately oriented.

The vibratory bowl feeder in the pharmaceutical industry is very concerned about hygiene standards. The entire disc body should be made of food-grade materials, no dead ends, and easy to clean, in line with FDA certification standards. For products such as tablets and capsules, food-grade coating should be added to the inner wall of the vibrating disc to prevent the material from directly contacting the metal. The vibrating discs used by some pharmaceutical companies will be equipped with air purification systems to ensure the cleanliness of the production environment.

The vibratory bowl feeder in the field of food packaging machinery values durability and hygiene standards. The disc body should be made of food-grade materials, and the surface should be mirror polished, which is easy to clean and disinfect. For different packaging materials, such as plastic bottle caps, metal can caps, etc., we can provide corresponding scratch-resistant designs.

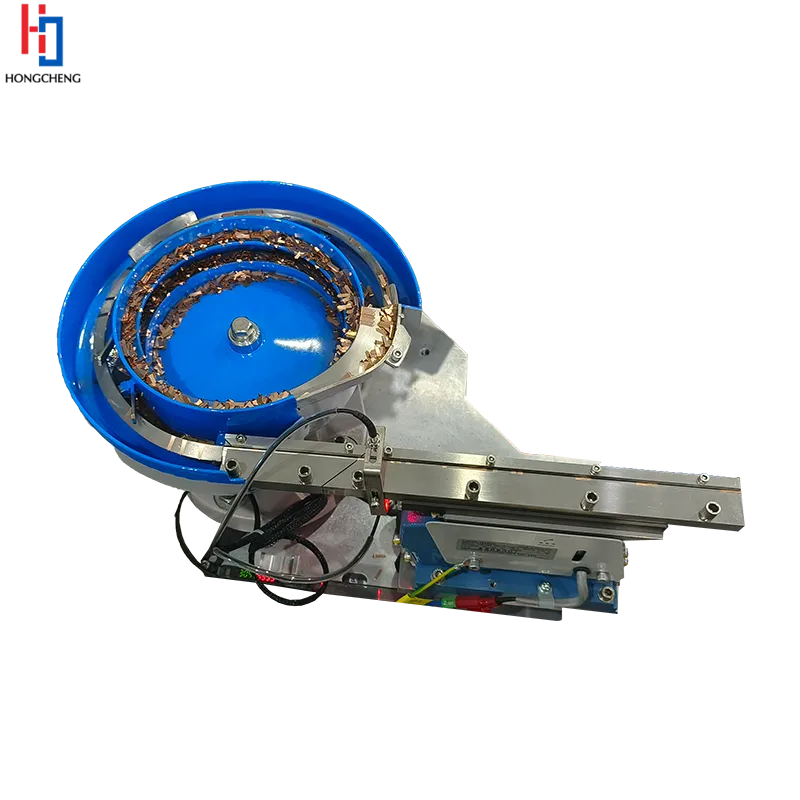

The high precision vibratory bowl feeder for parts in the heavy industry will value durability. The disc made of thickened steel plate can withstand the impact of hardware and auto parts. A buffer structure will be specially designed to keep the vibratory bowl feeder stable when conveying heavy metal parts. The thickened vibratory bowl feeder developed for brake pad manufacturers last year has remained intact for three consecutive years of work.

Shenzhen Hongcheng Automation Equipment Co., Ltd. has customization experience. We can adjust every aspect of the track design and control system according to demand. We can install anti-static devices for electronic-grade products; we have passed the aseptic certification for the food and pharmaceutical industry; heavy industry models can be customized with wear-resistant ceramic coatings.

We design difficult and high-quality bowl feeder systems and non-standard equipment to solve your many automation problems. Our production base has a test center. We will test all high precision vibratory bowl feeder for parts produced and deliver them to customers after passing the test. We have a perfect after-sales service system and excellent after-sales service personnel. If you are interested in our high precision vibratory bowl feeder for parts, please feel free to contact us!