The maintenance cost of aluminum bowl feeder is a concern for many industries. The high-quality material selection and structural design of the equipment we produce, and we take into account the convenience of late maintenance during production, so that users do not have to spend too much energy on maintenance in long-term use, reducing the maintenance cost of aluminum bowl feeder.

The aluminum bowl feeder we produce focuses on reducing the risk of maintenance. Our parts are made of durable materials. The vibration motor uses high-quality silent models, which have a longer life than ordinary feeders under normal use. The high-strength aluminum alloy used in the bowl body has been specially treated, and the wear resistance is greatly improved than that of ordinary aluminum. Even if you work continuously for 12 hours a day, the surface is not easy to scratch or deform. Our customer's aluminum bowl feeder has been used for 5 years. Except for regular replacement of lubricating oil, it has hardly been repaired. It has been well received by customers.

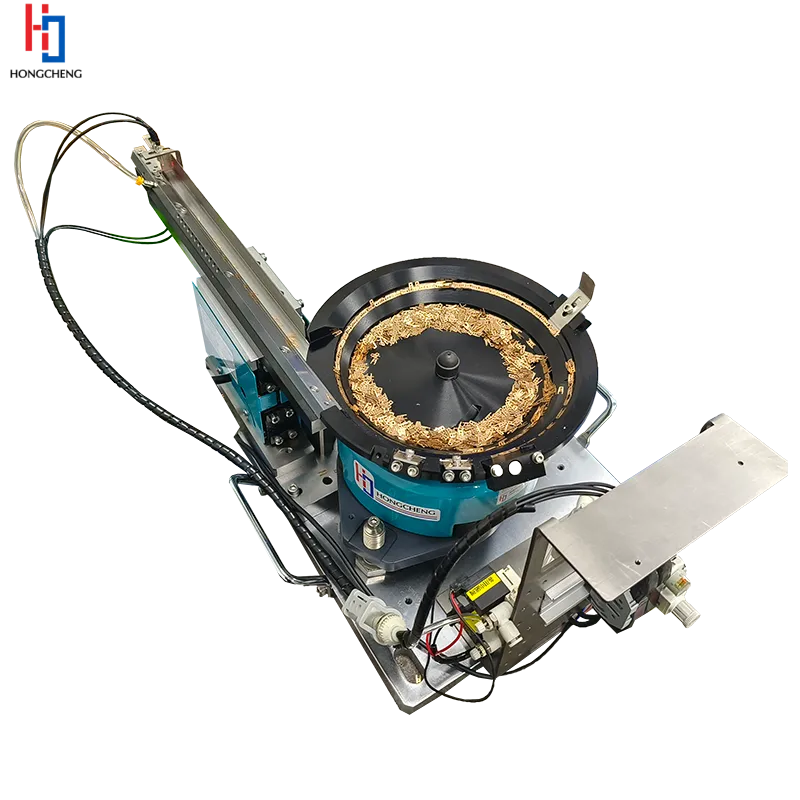

The key components of the equipment are all designed in a modular manner, such as the discharge port and the vibration spring, which are easily damaged and can be disassembled and replaced without professional tools. One of our food factory customers' vibratory bowl feeder for insulating chip has wear and tear at the discharge port. We provided a repair video. The repair workers did it themselves and replaced the new parts in 15 minutes. And we will also provide different installation and maintenance videos according to the intensity of use in different industries. We can also customize parts. For high-frequency use scenarios such as in the hardware industry, a layer of wear-resistant coating will be added to extend the replacement cycle of equipment, reduce the number of repairs of the vibratory bowl feeder for insulating chip, and reduce maintenance costs.

There are intelligent production lines in our workshop, and each line is equipped with testing instruments to ensure that the size of each accessory is within the standard. During production, we will make adjustments according to the customer's use environment. For example, in the humid southern region, the circuit interface of the vibratory bowl feeder for insulating chip will be waterproof, in the dusty workshop environment, the motor will be equipped with a dust cover. These customized designs allow our vibratory bowl feeder for insulating chip to operate stably in various scenarios, reducing maintenance requirements.

Shenzhen Hongcheng Automation Equipment Co., Ltd. it is a manufacturer specializing in the production of automatic feeding equipment. There are accessories in our warehouse to ensure the fastest delivery after customers place an order. The company's products have been widely used in light industry machinery, standard parts, connectors, bearing industries and other fields to help customers improve production efficiency. We also have a perfect after-sales service system. Standard model spare parts are in sufficient stock, and emergency failures will be responded to within 24 hours. If you are interested in our vibratory bowl feeder for insulating chip, please feel free to contact us!