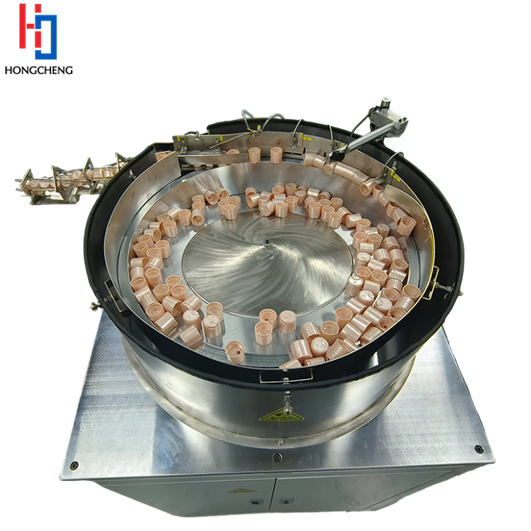

Through our customized design, centrifugal bowl feeders can not only transport small particulate materials, but also solve the problems of deviating from the correct position and stacking many materials together when conveying small particulate materials. Electronic components, pharmaceutical capsules, precision hardware and other industries have already used our centrifugal bowl feeders.

For the characteristics of small particulate materials, we will make many adjustments when customizing centrifugal bowl feeders. The surface of the turntable will choose different materials according to the shape and hardness of the particles. When conveying electronic parts with a diameter of 0.5mm, we will use plastic turntables. The edges of the plastic surface parts will not be scratched. For conveying hard hardware parts, replace them with wear-resistant aluminum discs. The service life is much longer than that of ordinary feeding discs.

We will also calculate the width and slope of the centrifugal bowl feedersdischarge track. For conveying ball-shaped particles, ribs will be installed on both sides of the track to ensure that the material will not roll off. For conveying flat particles, the track will be designed as a lower arc in the middle, allowing the materials to be arranged automatically.

The rotary feeder for battery parts we produce can be customized according to the specific parameters of small particulate materials. The weight of the particles is different, and the centrifugal force is different. Light materials like plastic particles will lower the speed of the turntable. Small metal particles are relatively large, which will increase the speed. Cushioning pads are installed at the discharge port to reduce the impact of the material when it falls. For small-particle capsules in the pharmaceutical industry, our rotary feeder for battery parts will use a fully enclosed design to prevent dust pollution. All parts that come into contact with the material are treated aseptic and meet hygiene standards.

The production lines in our workshop are equipped with special testing instruments. For small particle conveying equipment, standard particles will be repeatedly tested to ensure that the hourly conveying error does not exceed 50.There are many accessories of different specifications in our warehouse. When customers have special needs, we use the fastest time to complete the assembly and commissioning of rotary feeder for battery parts.

Shenzhen Hongcheng Automation Equipment Co., Ltd. It is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for feeder systems. We use advanced equipment to develop and design difficult and high-quality feeder systems and non-standard equipment to solve your many automation problems. We also have a perfect after-sales service system and excellent after-sales service personnel. If you are interested in our rotary feeder for battery parts, please feel free to contact us!