Compared with traditional vibration plates, vibratory bowl screw feeder has many obvious advantages. Many customers will ask when selecting: What is the difference between these two devices? Simply put, vibratory bowl screw feeder is not only lightweight, but also flexible in customization and stable in operation. It is particularly suitable for automation scenarios that have certain requirements for feeding rhythm and equipment aesthetics.

Aluminum is much lighter than stainless steel, which is more convenient during processing and installation. Especially when space is limited or equipment needs to be moved frequently, the lightweight aluminum bowl is undoubtedly more labor-saving. At the same time, aluminum has good thermal conductivity and is not easy to accumulate heat during operation, which is very practical for customers who work continuously for a long time. Many customers worry that aluminum is not strong enough, but there is no need to worry. The vibratory bowl screw feeder we produce uses high-strength aviation-grade aluminum with high processing precision and good wear resistance. With anodizing or sandblasting surface treatment, it is not only more scratch-resistant, but also looks very technological.

When it comes to operating effects, cast aluminum vibratory feeder bowl is more sensitive and responsive when used with vibration drivers, especially suitable for lightweight and small-sized parts, such as electronic components, medical plastic parts, small screws, etc. In situations where the beat is required to be fast, cast aluminum vibratory feeder bowl can often run more steadily and accurately than traditional stainless steel vibration plates. And because of its light weight, lower energy consumption, and less vibration noise, it is more comfortable to use.

The HONGCHENG factory currently focuses on customizing various types of cast aluminum vibratory feeder bowl, and has served many industry customers including electronic manufacturing, medical equipment, plastic processing and automotive parts. In terms of production equipment, we have multiple CNC precision machining centers and automatic grinding, polishing, and spraying equipment to ensure that the dimensional tolerance of each aluminum bowl is controlled within ±0.05mm, and the finish meets customer requirements. The structure of the inner cavity of the aluminum bowl can be specially designed according to the shape of the material to avoid the problem of material jamming and material jumping, and improve efficiency.

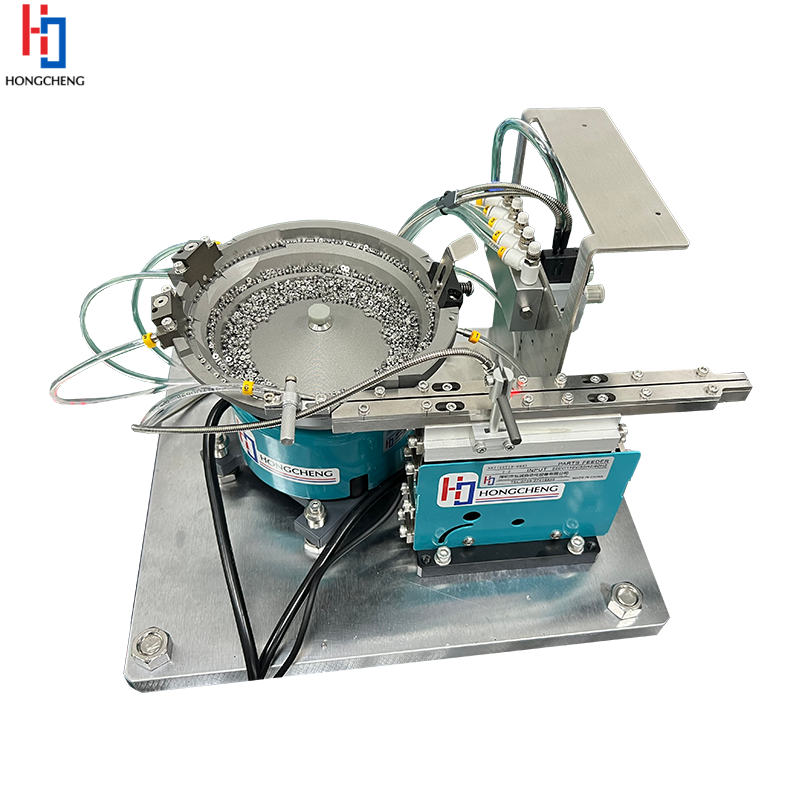

We also provide a complete set of feeding system solutions, including vibration bases, controllers, linear feeders, etc. After customers get the equipment, they can be directly integrated into the existing automation line without tedious debugging. For special materials or special working conditions, our engineering team can also carry out non-standard customization, from bowl design to drive parameter configuration, one-to-one service to ensure that customers use it smoothly.

At present, our cast aluminum vibratory feeder bowl has a full range of specifications, from small-diameter φ80mm to large-size φ800mm, there are spot or customizable models. Whether it is sample proofing or batch delivery, we can respond quickly and have stable delivery. Especially in the early stage of product development, customers often need to frequently adjust the feeding structure. Our vibratory bowl screw feeder is very suitable, with a short processing cycle and convenient modification, which greatly speeds up the trial production progress.

If you are considering upgrading your production line or looking for a suitable feeding solution for a new product, you might as well talk to us. Bring your sample materials, we can help you test on-site, and even draw and proof. Choose a suitable set of vibratory bowl screw feeder to make feeding efficient, easy and beautiful. Maybe this is your little secret to increase production capacity! Feel free to contact us at any time to make automation easier together.