The compatibility between cast aluminum vibratory feeder bowl and vibration drive device is very good. Many people ask, will the aluminum material be too light and unstable when vibrating? In fact, it is not the case. Because of the lightness of aluminum and our professionally designed structure, cast aluminum vibratory feeder bowl is more flexible and responsive when used with vibrators, and can stably arrange and output various small parts. Especially in automation scenarios that require high beats and light loads, the performance of aluminum bowls is very outstanding. It is energy-saving, low noise, and long life. It is a practical and economical feeding tool.

Our cast aluminum vibratory feeder bowl is widely used in electronics, plastics, medical, hardware, automotive parts and other industries. It is suitable for processing a variety of regular or slightly irregular materials such as screws, springs, plastic parts, small electrodes, etc. The surface of the aluminum bowl can be anodized, non-slip sandblasted or fluorocarbon sprayed according to different working conditions. It is not only beautiful and wear-resistant, but also reduces material jamming and improves feeding efficiency. If additional wear resistance is required, we can also add a shockproof layer or special coating to the bowl to ensure smooth material operation.

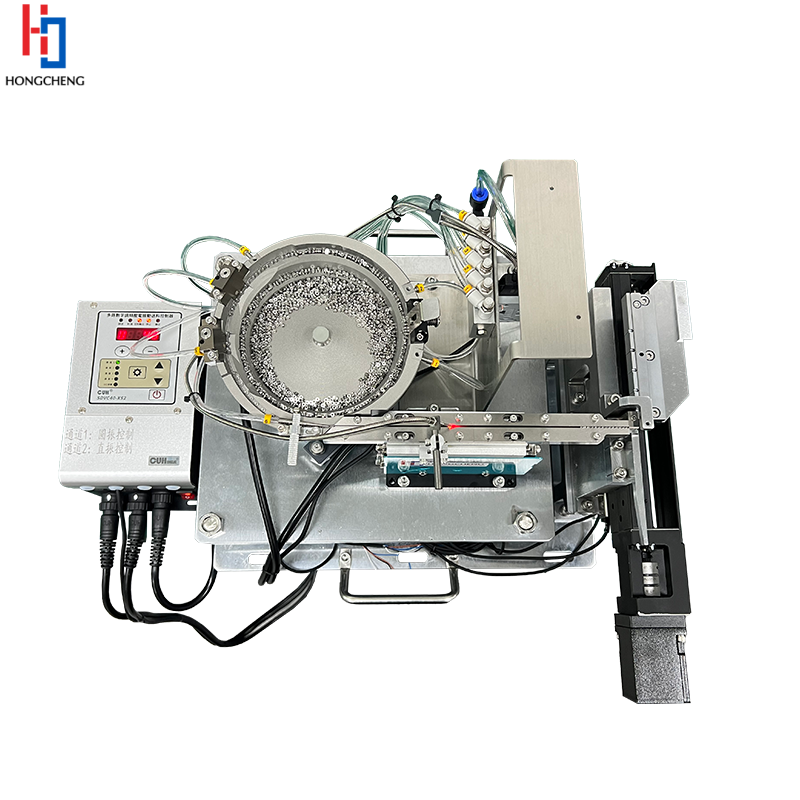

Some customers are also worried about versatility, such as whether it can be used with existing vibrators and electronic control systems. No problem. The cast aluminum vibratory parts feeder we produce is designed with a variety of vibration drive bases in mind, including common linear vibrators, electromagnetic vibrators, composite drivers, etc., which are highly versatile and easy to replace and integrate. Our engineering team can also customize interfaces or structures for customers on site to ensure perfect docking without major changes to the original equipment.

Our production plant currently has multiple CNC machining centers, CNC lathes and automatic polishing equipment. All aluminum bowls are processed from high-quality aluminum ingots, one-piece molding, high strength, light weight, and precision controlled within ±0.05mm. Whether you are making small batch samples or large batch orders, we can deliver on time. Our engineering team has rich experience in non-standard design and can provide exclusive solutions based on the size, shape and weight of customer products.

In order to meet the needs of more customers, we are also constantly expanding the size range and types of cast aluminum vibratory parts feeder, including multiple models with inner diameters ranging from 80mm to 800mm. Do you want large-capacity loading? Or precision micro-parts arrangement? We can tailor it for you. Each cast aluminum vibratory parts feeder is rigorously tested before leaving the factory, including full-load operation, vibration stability, noise level, and automatic identification and adjustment functions, to ensure that the equipment you get is plug-and-play and reliable.

If you are now planning to purchase an efficient feeding system, and you want the equipment to be light, beautiful, and easy to install, you might consider our cast aluminum vibratory feeder bowl. Don't worry about compatibility, life, and maintenance. We provide full technical support from selection to integration, so that you can use it with peace of mind. If you like, you are welcome to bring your materials directly to the HONGCHENG factory for on-site testing. We are happy to tailor a solution for you.