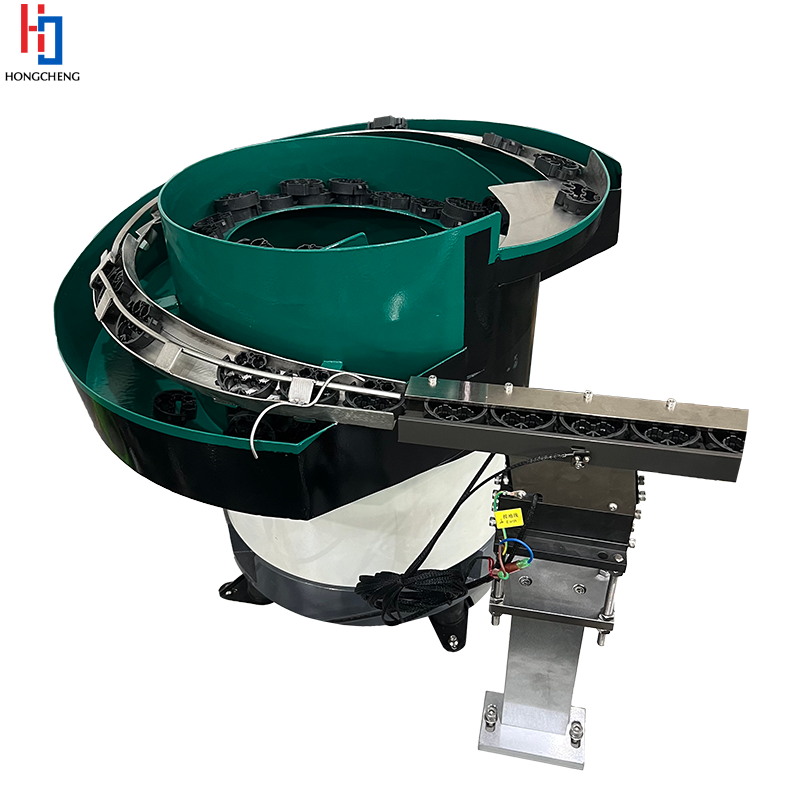

How to integrate automatic vibratory bowl feeders into the automated production line? It is not complicated, but it also requires some skills. Generally speaking, Automatic Vibratory Bowl Feeder is used to provide a stable and continuous supply of small parts to the production line. It can automatically arrange the messy small parts and send them to the designated location. In order to make the entire production line run smoothly, we only need to put automatic vibratory bowl feeders at the beginning, cooperate with the feeding controller, track conveying system and the assembly or detection equipment at the back end, and we can successfully complete the automatic docking.

For example, in the electronic parts assembly line, automatic vibratory bowl feeders can neatly send capacitors to the front of the placement machine, saving manual operation; for example, in the assembly of medical devices, small syringes or plastic caps are automatically arranged by the bowl feeder and then transported to the injection equipment or packaging station, which greatly improves the beat efficiency. In the hardware industry, we are more often used to accurately feed various screws and nuts into the assembly head through automatic vibrating system to achieve automatic tightening, detection and packaging.

In order to ensure smooth docking with automated equipment, the Automatic Vibrating System we produce supports a variety of communication interfaces, such as PLC control, RS485, sensor linkage, etc., which can be easily connected to various automated control systems. Whether your production line is newly built or an old line is upgraded, we can provide customized installation solutions according to process requirements. Our equipment has a compact structure, stable operation, small footprint, simple maintenance, and is suitable for a variety of complex scenarios.

HONGCHENG is an automatic vibrating system manufacturer with many years of experience. It has a wide range of products, including vibration, centrifugal, disc, compound and other types, which are suitable for various small parts feeding needs. Our engineering team is not only familiar with feeding equipment, but also has a deep understanding of automation control logic. It can help customers design the entire production rhythm docking solution, from sensor layout to signal control to track length adjustment, and can provide one-stop service.

At present, our factory is equipped with high-precision processing equipment and multiple assembly lines, with high production efficiency and short delivery cycle. We use high-quality materials and high-performance electronic control components to ensure the stable operation of each device. Each automatic vibrating system will be tested under simulated working conditions before leaving the factory to ensure that it can be quickly integrated at the customer site without secondary debugging. Our automatic vibrating system has been widely used in electronics, automobiles, medical, hardware, toys and other industries, with customers at home and abroad.

Whether you are doing parts assembly or upgrading the entire line, if you are considering how to make your automated production more efficient, automatic vibratory bowl feeder will be a good choice for you. If you are worried about not knowing how to install or integrate, it doesn't matter, our technical team can provide online support or on-site guidance, so that you can buy with peace of mind and use with ease.