The following is our series of articles, if you are interested, you can click to view:

The previous two articles introduced to you the methods of vibratory bowl feeder for handling wet materials, including: designing special materials, designing anti-stick equipment, installing a heating system for the equipment, adjusting the vibration parameters of the machine, adjusting the tilt angle, and installing anti-blocking devices. This article will continue to introduce the method of handling wet materials by the vibratory bowl feeder.

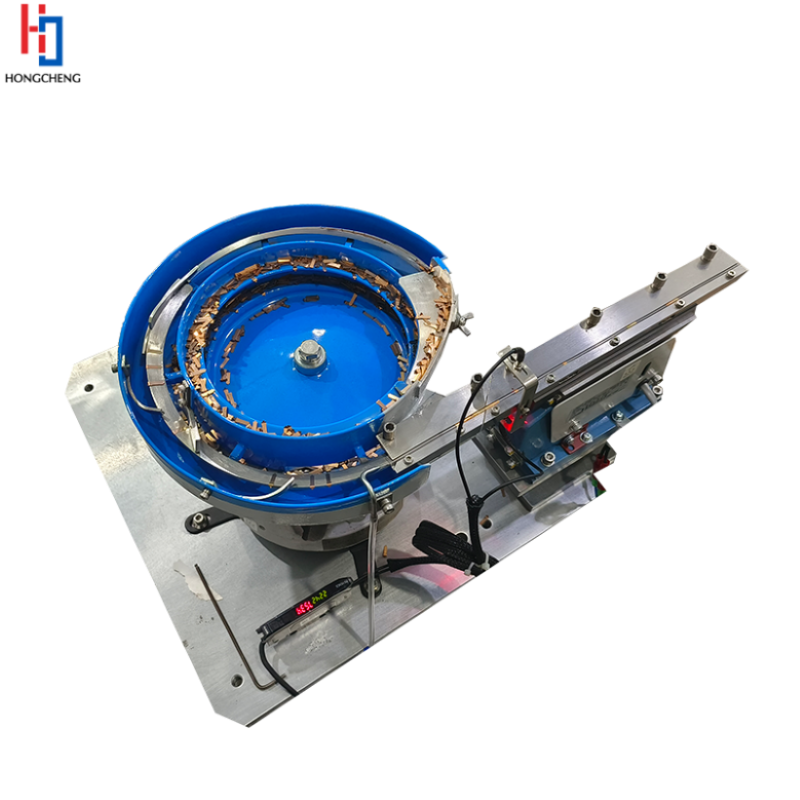

Vibratory bowl feeder method for handling wet materials:

1. The combination of vibratory bowl feeder and auxiliary equipment can improve operating efficiency. For the degree of adhesion of different materials, cleaning devices such as scrapers or brushes can be customized to rotate synchronously with the vibration of the equipment for cleaning. For materials with slightly larger particles, wear-resistant rubber scrapers are selected. The edges of the scrapers are designed to be curved to fit the curvature of the machine, and they are automatically cleaned when the equipment is down, so that the materials will not accumulate in the corners. Some customers have strict requirements for the production environment, and they can also customize auxiliary devices with vacuum function to suck away dust generated during work during cleaning, keep the vibratory bowl feederclean and improve the working environment.

2. To control the amount of material entering the vibratory bowl screw feeder system. According to the customer's hourly processing capacity, the feed volume is stabilized within the rated load of the equipment. If customers need to use it in conjunction with other equipment, they can install an intelligent control system to transmit the feed volume data to the production line platform, which can automatically adjust the feed speed according to the operating status of downstream equipment, so that there will be no problem of excessive feed clogging.

3. The vibratory bowl feeder should be cleaned and maintained regularly. Easy-to-wear parts such as scrapers, brushes, etc. are designed to be quickly removed, and replacement is very simple without professional tools. Some machines can customize the maintenance reminder function. After the equipment is running for a set length of time, the control panel will automatically display maintenance reminders. The operator must complete regular cleaning and component inspections to ensure that the vibratory bowl screw feeder system is in good operating condition.

We can provide customized services for the vibratory bowl screw feeder system. We can customize the material, size, and style. We can also adjust according to customer needs to ensure the production of products that customers are satisfied with. The products customized for customers before have also been well received by customers.

Shenzhen Hongcheng Automation Equipment Co., Ltd. it has a perfect after-sales service system and excellent after-sales service personnel. Our logistics speed is also very fast, ensuring that the products will be delivered to customers within the specified time. The above three articles are the methods of the vibratory bowl screw feeder system to deal with wet materials. If you have any content that you are interested in, you can also tell us. If you have any questions, please feel free to contact us!