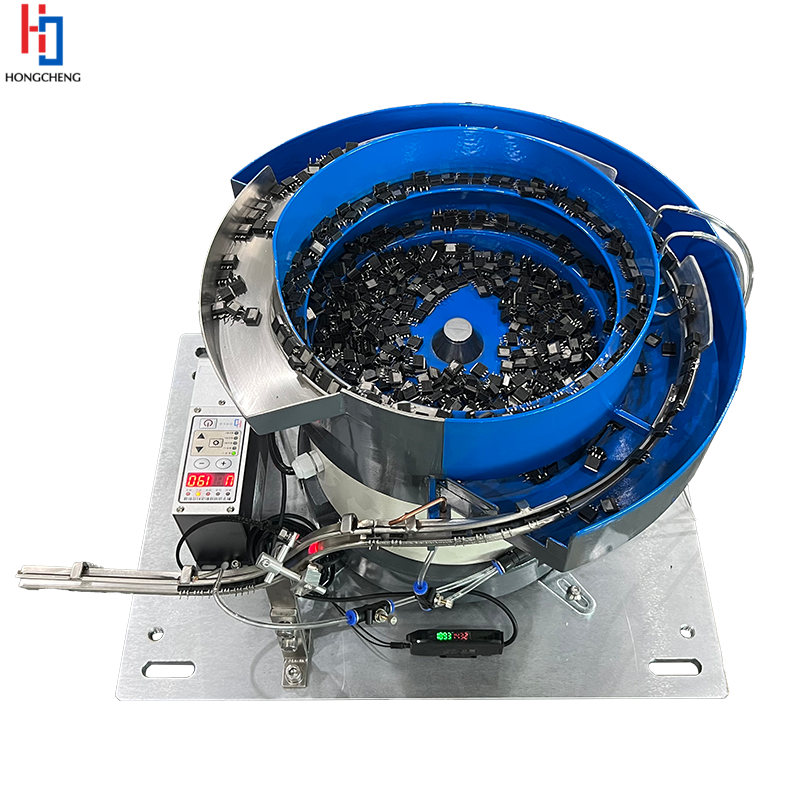

In the hardware and electronics industry, parts are often small in size, complex in shape, and large in quantity. Manual sorting is not only time-consuming and laborious, but also prone to errors. In order to improve production efficiency, more and more companies choose to use Electronic Part Hardware Vibration Bowl Feeder to achieve automated feeding.

In the hardware industry, our bowl feeder is often used to feed the following types of parts:

Small screws, nuts, washers

Springs, pins, rivets

Electronic connectors, terminal pins

Mobile phone shell parts, buttons, metal buckles

LED housing, USB plug, electronic switch housing

The common characteristics of these parts are small size, large quantity, and low manual operation efficiency. And our Electronic Part Hardware Vibration Bowl Feeder can arrange and transport them in an orderly, directional, and continuous manner, laying a good foundation for the next step of assembly or testing.

Non-standard customization:

Speaking of this, someone may ask: The parts I use are different from others, and the shape is very strange. Can this kind of thing be delivered?

Of course! HONGCHENG is a professional non-standard customized Electronic Part Hardware Vibration Bowl Feeder. Each set of Automatic Vibratory Bowl Feeder is tailored to the customer's part samples or drawings to ensure stable and smooth feeding.

We can customize for you:

| Customized project | Function description | Applicable scenarios or advantages |

| Special track design | Customize the track curve according to the shape of the part to improve the feeding stability | Adapt to special-shaped and irregular parts |

| Dual-channel, dual-export design | Realize simultaneous feeding to two stations to improve efficiency | Multi-station parallel operation to improve overall rhythm |

| Add dust removal and anti-static functions | Prevent dust accumulation and static interference to ensure stable operation | Electronic components, precision parts production line |

We support sample proofing service - as long as you send us the sample, we can help you test the feeding effect and provide a technical solution, so that you can place an order with more peace of mind.

Have you ever had the trouble of parts not being able to be fed?

Have you ever chosen a feeder, but found that the parts are always stuck, not neat, and feeding slowly? In this case, it is mostly because the track does not match, or Automatic Vibratory Bowl Feeder has not customized the design for your product characteristics. If you have had this experience, please leave a message to tell us, we will analyze the problem for you free of charge and provide appropriate Automatic Vibratory Bowl Feeder suggestions. If you are willing to visit our factory, you will learn more.

Welcome all kinds of hardware and electronics industry customers to contact us for consultation and cooperation!

📩 Contact information:

Email: rubysun@szhcfeeders.com

WhatsApp: +86 18742554256