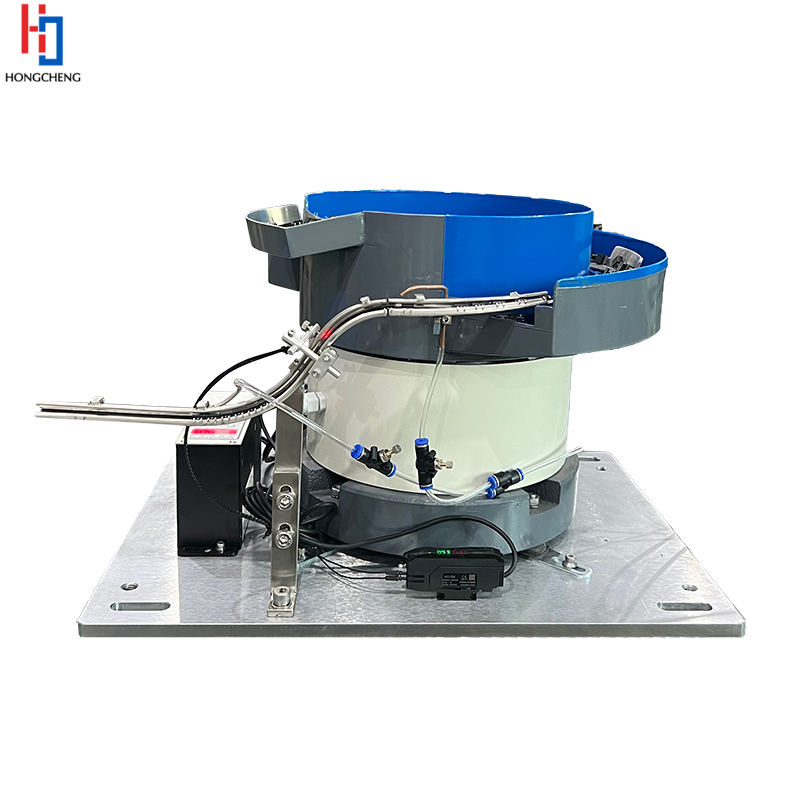

Automatic Vibratory Bowl Feeder is almost an indispensable part of the automated production line. It is responsible for delivering parts to the next process in an orderly manner, greatly improving production efficiency. However, many customers often encounter a problem in actual use: the speed is not right, either too fast to cause parts to pile up and jam, or too slow to keep up with the beat.

How to adjust the speed of Automatic Vibratory Bowl Feeder?

Most of the vibration motors of bowl feeders are equipped with speed controllers. We only need to fine-tune the frequency and amplitude through the knob or CNC panel to accurately control the rhythm of feeding.

For example, if you want to feed the parts faster, you can try to increase the frequency, but at this time you must observe the running conditions in the bowl body-does the part jump out of the track? Is there any accumulation?

If you find confusion, it means that the Automatic Vibratory Bowl Feeder speed is too fast, and you should adjust it down appropriately and observe it again. When slowing down, if the Automatic Vibratory Bowl Feeder speed is too low, the "parts can't move" may occur. Finding the right rhythm point is the key to using a bowl feeder. Before we leave the factory, we will conduct preliminary debugging for customers to ensure that they can be plugged in and used. If you encounter different parts changes, you can also contact our engineers at any time to assist in remote guidance.

To use it correctly, you must also pay attention to these small details.

Many customers feel that Vibratory Bowl Feeder is not very sensitive after using it. In fact, most of them are because they ignore daily maintenance.

Clean Vibratory Bowl Feeder regularly: dust, oil stains, and debris will affect the smooth operation of the feeding track.

Avoid overload: Putting too many parts into Vibratory Bowl Feeder at one time will cause problems such as jamming and uneven vibration.

Check the consistency of parts: If the size difference of parts is too large, it will easily affect the feeding effect of Vibratory Bowl Feeder.

We recommend that you do a simple test before changing different products each time, and make slight adjustments to the track, the effect will be more ideal.

We can customize it for you!

The shape and size of each customer's parts are different, so it is difficult for standardized equipment to adapt to all production conditions. Our factory provides non-standard customized bowl feeder services, tailor-made according to the customer's part samples:

| Customized project | Functional description | Applicable scenarios or advantages |

| Special track design | Customize track curve according to part shape to improve feeding stability | Adapt to special-shaped and irregular parts |

| Dual-channel, dual-export design | Simultaneous feeding to two stations to improve efficiency | Multiple stations work in parallel to improve overall rhythm |

| Add dust removal and anti-static functions | Prevent dust accumulation and static interference to ensure stable operation | Electronic components and precision parts production line |

| Seamless connection with robots and assembly lines | Reserve signal interface and position for convenient linkage control | Automated assembly and visual recognition system |

As long as you tell us your needs, send samples or drawings, our technical team can develop a special solution for you!

Have you ever encountered AVibratory Bowl Feeder jamming?

If you have also encounteredVibratory Bowl Feeder-related problems at the production site, you may as well leave a message to tell us, we can make optimization suggestions for you, or even redesign a set of track structures to solve the problem. Of course, if you are still in the selection stage, please contact us for free consultation, and we will give professional recommendations based on the parts information you provide.