This is a question that seems simple, but the answer is not so absolute. If we look at it from the perspective of weight and structural design, Automatic Vibratory Bowl Feeders is usually lighter, and the energy required for vibration is naturally less, so in many light-load usage scenarios, Bowl Feeder Vibrating will indeed save more power. But if the accuracy, stability and beat requirements are also taken into account, it cannot be generalized.

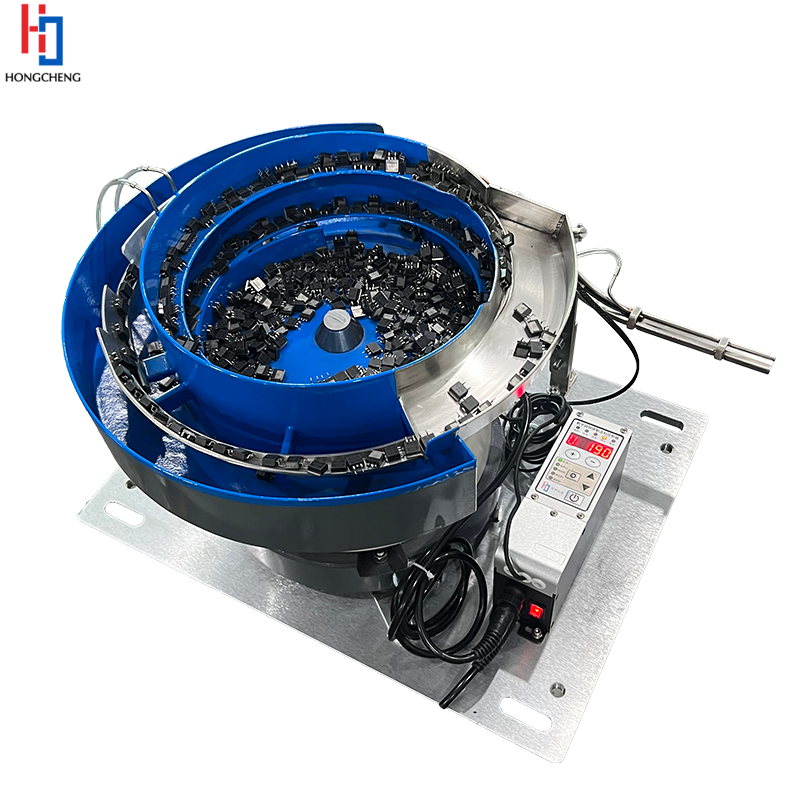

Due to its light material and flexible processing, Bowl Feeder Vibrating is particularly suitable for use in production lines with low rhythm, light products and frequent operations, such as pharmaceutical packaging, electronic component sorting, and feeding of small plastic parts.

Bowl Feeder Vibrating has a lighter bowl and can achieve low-energy operation with a low-power drive.

Bowl Feeder Vibrating also has lower operating noise, which is particularly suitable for workshops with high requirements for quiet environment.

If you are facing a scene with complex structure, heavy parts or high requirements for stability, aluminum Bowl Feeder Vibrating may be more effective.

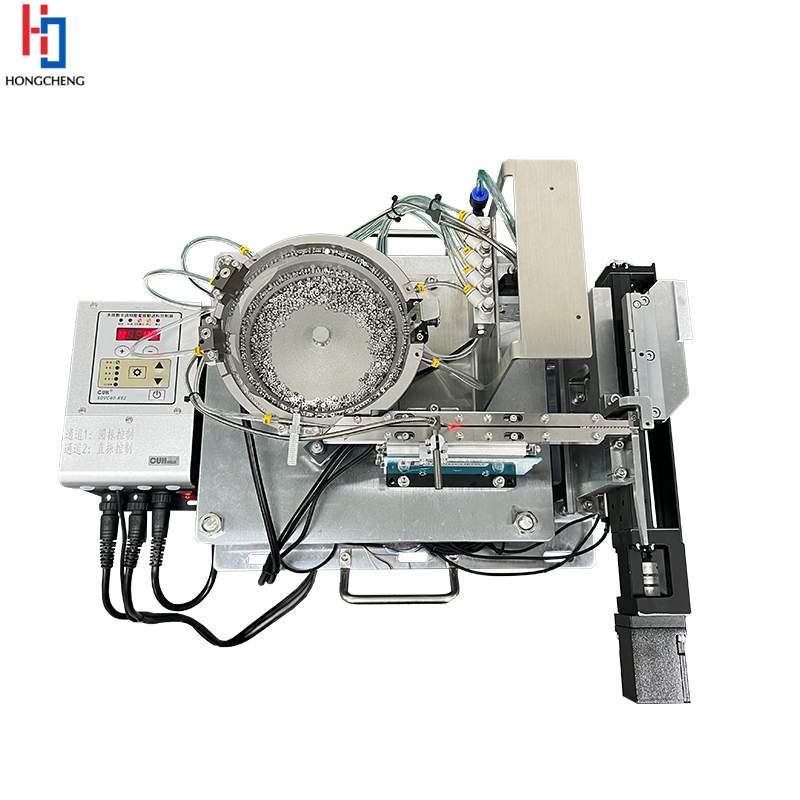

Although aluminum Automatic Vibratory Bowl Feeders is heavier than plastic, its vibration response is more stable, its service life is longer, and it is not easy to produce displacement deformation due to long-term vibration.

In medium and high-beat automation equipment, aluminum Automatic Vibratory Bowl Feeders performs better. Although the power consumption is slightly higher, the stability and efficiency often bring greater overall energy saving effects.

No matter which material is suitable for you, we can meet it. Our factory focuses on the production of Bowl Feeder Vibrating and aluminum Automatic Vibratory Bowl Feeders, supports non-standard customization, from small batch trial production to large-scale supply, the equipment structure is flexible, and compatible with a variety of workpiece sizes and materials.

Hongcheng Factory has perfect design, processing, and assembly integration capabilities. The equipment is exported to Southeast Asia, Russia, South America and other countries, and has served customers in many industries such as electronics, auto parts, medical, packaging, and hardware. Whether you are opening a new factory or upgrading old equipment, we can give the most appropriate suggestions and energy-saving solutions according to your workshop environment.

If you are purchasing Bowl Feeder Vibrating, please talk to us about your product characteristics, production rhythm and on-site conditions. We are not just selling equipment, but also a reliable partner to help you save time, manpower and electricity. Welcome to contact us to customize a set of energy-saving and efficient solutions for you, and take a look at our production process and actual material demonstration on site. You will be shocked by our process!