This is a question many customers ask when purchasing vibrating feeders. The answer is - yes, aluminum Bowl Feeder Vibrating does perform more stably and durable in high temperature environments. Especially in some places with high working temperatures, such as injection molding workshops, near drying lines, and heat treatment areas, aluminum Bowl Feeder Vibrating has better thermal conductivity and temperature resistance, and will not deform or crack after long-term use.

In contrast, bowl feeders are prone to various conditions in high temperature situations. Although plastic materials are light, they may soften or fatigue and age when exposed to heat, and long-term high temperatures can easily affect the vibration frequency and feeding rhythm. However, it is not completely useless. In industries such as electronic assembly lines and pharmaceutical packaging lines that are at room temperature, clean, and without high heat sources, Bowl Feeder Vibrating is very flexible, light and quiet, and the price is relatively more economical and easy to carry.

Many customers are curious whether we make both materials? Of course! Our factory has been producing plastic feeders and aluminum feeders for a long time, with a full range of models, compact structure, and support for customized services. Whether you need a lightweight and easy-to-carry plastic bowl or a durable and heat-resistant aluminum bowl, we can provide professional matching according to your product size, weight and production rhythm to ensure smooth feeding, stable rhythm and improved efficiency.

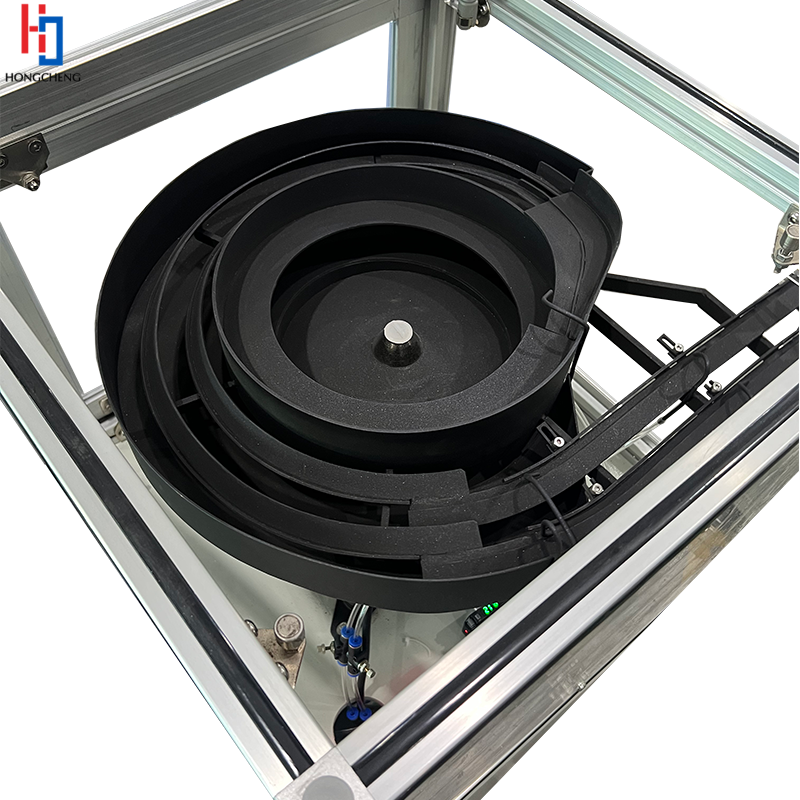

The Bowl Feeder Vibrating we produce is made of high-strength engineering plastics. After multiple vibration tests and durability verification, it is not only light in weight and low in noise, but also supports customization of special-shaped parts. It is especially suitable for production environments with limited space or frequent replacement of parts. The aluminum Bowl Feeder Vibrating uses high-strength aviation aluminum alloy. After CNC precision machining, the vibration conduction performance is more uniform, which is suitable for work sites with higher requirements for stability and high temperature resistance.

It is no exaggeration to say that our Bowl Feeder Vibrating has served hundreds of automation equipment manufacturers across the country, and its products are exported to Southeast Asia, Russia, the Middle East and other places. The Hongcheng factory is equipped with a complete CNC machining center, laser cutting machine, and automatic winding equipment. Each process is strictly controlled to ensure stable equipment delivery and smooth operation.

If you are struggling to choose which material for the bowl body, you may wish to contact us for a chat. Tell us your usage scenario, temperature range, material size, and we can give you the most appropriate suggestions, or even send you a sample for your testing experience.