In a modern production workshop, the noise of the equipment when it is running affects the working environment very much. How loud is the vibratory bowl feeder when it is running? Generally speaking, during the operation of the traditional vibrating bowl feeder, due to the friction between the material and the equipment and the operation of the machinery, it will produce a certain amount of noise, usually between 70-90 decibels. Being in such an environment for a long time not only affects the health of workers, but also interferes with the operation of other equipment. And our vibrating bowl feeder adopts mute technology to improve the working environment in the workshop.

The vibratory bowl feeder we developed adopts a noise-reducing design. The feeder has a special sound insulation cover, which is equipped with sound-absorbing materials, which can effectively absorb the noise generated during vibration. After optimizing the system, the sound of metal collisions is also reduced. The low noise allows the equipment to operate stably even in industries with high environmental requirements such as precision electronics and food processing, creating a quiet and comfortable production environment for enterprises.

In addition to good mute performance, our vibrating bowl feeder is also very good in terms of stability. We use a precision control system, and the vibration frequency can be adjusted to ensure that different materials can be transported smoothly. The design of anti-jamming material solves the common material blocking problem of traditional equipment, and the production efficiency is increased by more than 20%.Cleaning and maintenance have also become simpler, reducing downtime.

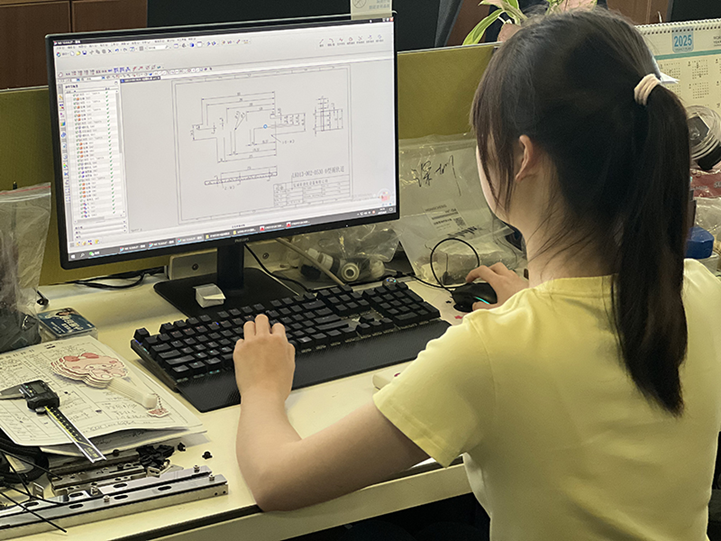

Our company has customized production capacity. The production needs of different industries and enterprises are different, and it is difficult for standardized products to meet the actual production requirements. Therefore, we have formed a professional technical team, which can tailor an exclusive vibrating bowl feeder for customers based on the specific needs of customers, from material characteristics, production environment, production capacity requirements and other aspects. For example, for the transportation of some special materials, we can perform special treatment on the interior of the equipment so that the materials will not stick to the inner wall. In some production workshops with limited space, we can also design small equipment to save floor space.

Hongcheng is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for the vibratory bowl feeder system. We use advanced equipment to develop, design, difficult and high-quality vibratory bowl feeder systems and non-standard equipment to solve many of your automation problems. If you are interested in our vibratory bowl feeder, please feel free to contact us!