In the cosmetic production line, the precise supply of bottle caps affects the packaging efficiency. The traditional bottle cap supply method relies on manual or simple vibration discs, which are not only slow, but also prone to problems such as stuck materials and reverse caps, resulting in frequent production line shutdowns. The current centrifugal feed system for cap has improved the efficiency and stability of cosmetic bottle assembly through automated and intelligent design.

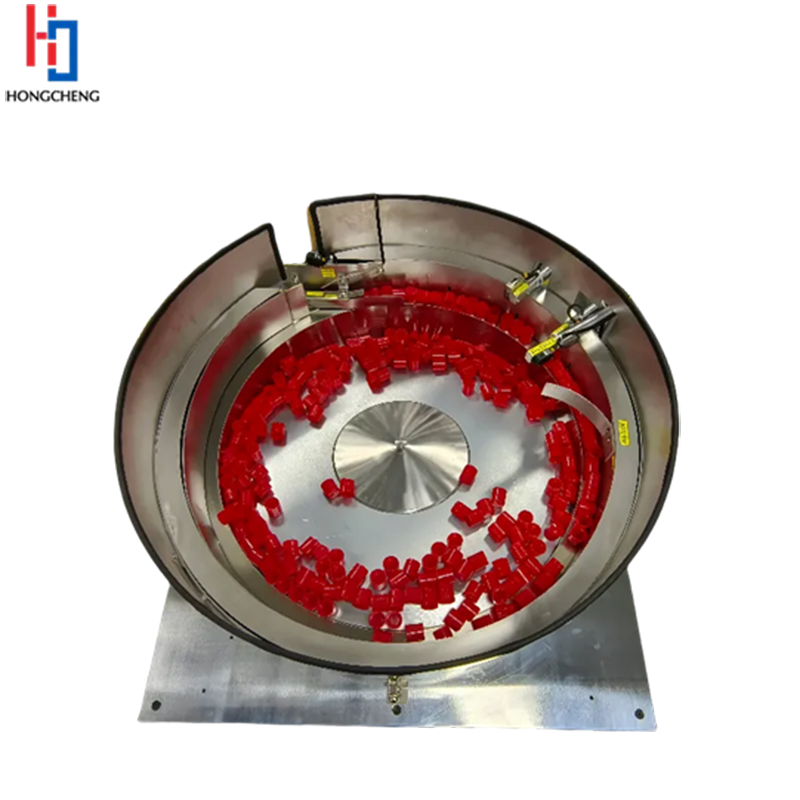

The advantage of centrifugal feed system for cap is fast and accurate feeding. Centrifugal feed system for cap adopts flexible vibration technology and positioning system, which can stably transport the bottle cap at a speed of 200-500 per minute, and the direction is consistent to ensure that it matches the bottle body. Compared with manual feeding, the efficiency is increased by more than 3 times, and at the same time, the leakage rate is reduced by a lot due to the wrong cover. The anti-stuck design of the Cap Feeders Centrifugal solves the problem that the special-shaped bottle cap is easy to get stuck, and the production line can run continuously for 24 hours.

The Cap Feeders Centrifugal we produce attaches great importance to adaptability. There are many styles of cosmetic bottles, round, square, caps with sprinklers, and patterns. These differences can be adapted to our machines. If the production line is replaced with a new bottle type, simply adjust the parameters of the machine, and the work can continue. If there are special specifications, we can also provide customized services, specially designed according to the size, weight and shape of the bottle cap, so that the machine and the production line can be matched, without having to change the product design for the equipment, which improves production efficiency.

The material and structure of the machine are also very important. We use smooth and wear-resistant materials for the part that touches the bottle cap, which will not scratch the surface of the cosmetic bottle. The noise is low during operation and there will be no additional interference. Our factory has a professional R&D team, strict process control from design to production, and can respond quickly according to customer needs. Whether it is small-batch customization or large-scale production, the stability and efficiency of our Cap Feeders Centrifugal can be guaranteed, so that every cosmetic assembly line can use suitable feeding equipment.

Shenzhen Hongcheng Automation Equipment Co., Ltd. Advanced production equipment guarantees efficient and stable production capacity. The company has a perfect after-sales service system and excellent after-sales service personnel, and we will continue to invest in research and development to ensure that our products are technologically advanced and meet the latest industry needs. If you are interested in our Cap Feeders Centrifugal, please feel free to contact us!