The noise problem of equipment operation affects the work and health of workers. In a high-precision production environment, it may also interfere with the production process. The centrifugal feeders in automation we produce is a good choice, so how does the centrifugal feeders in automation achieve silent operation? This article will be described in detail.

The silent operation of centrifugal feeders in automation is achieved through technical optimization. The shell of the equipment uses special composite materials, which are filled with sound-absorbing materials, which can block the vibration and noise generated during mechanical operation. In addition, the core components of centrifugal feeders in automation have been balanced to reduce the friction and vibration of high-speed rotation. The motor part uses low-noise frequency conversion technology to ensure power output while reducing operating sound. Through the use of these technologies, the equipment can maintain low noise during high-speed operation and meet production scenarios with strict mute requirements.

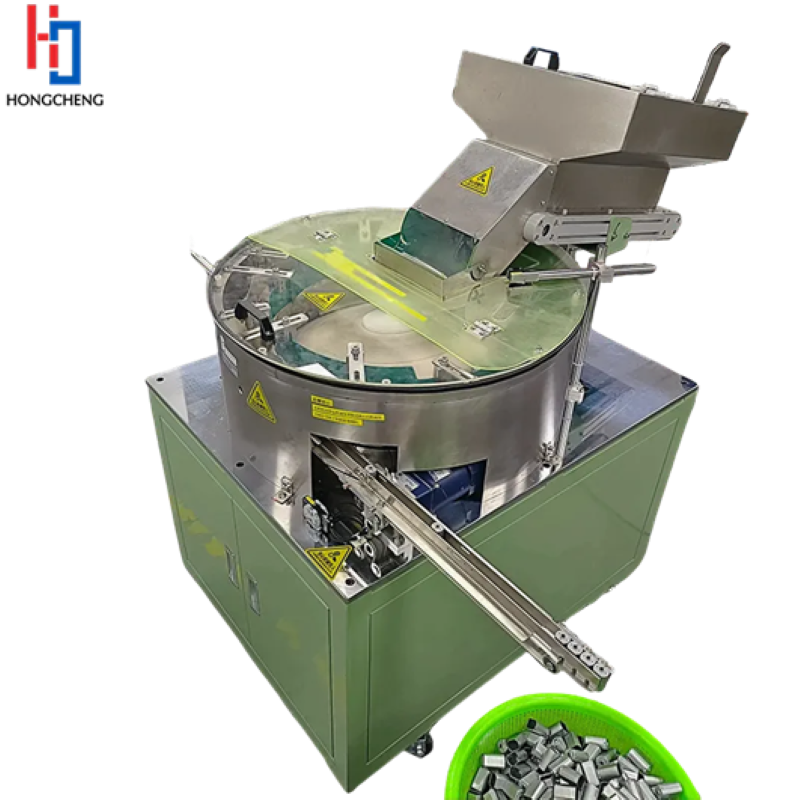

In addition to silent performance, centrifugal separators with integral feeder also has efficient and stable feeding capabilities. The centrifugal structure ensures that the material is transported evenly and will not cause clogging. The design of centrifugal separators with integral feeder also facilitates maintenance and cleaning, extending the service life. In the chemical, food or pharmaceutical industries, centrifugal separators with integral feeder can provide reliable solutions.

We provide comprehensive customized services, from the material selection of centrifugal separators with integral feeder to the functional configuration, which can be adjusted according to the actual needs of customers. For example, for the food industry, we can use food-grade materials to ensure hygiene and safety, for highly corrosive environments, it is recommended to use corrosion-resistant alloy housings to enhance the durability of the equipment and ensure that every centrifugal feeders in automation can be adapted to the customer's production line.

We have a strict quality control system. From the purchase of raw materials to the delivery of finished products, every step is strictly tested to ensure the stability and reliability of centrifugal feeders in automation. We provide perfect after-sales service.

Shenzhen Hongcheng Automation Equipment Co., Ltd. Our products have been widely used in food processing, pharmaceutical manufacturing, electronic components and other industries. The stable performance of our products and our intimate service have been recognized by cooperative enterprises. We will continue to develop silent technology and launch more innovative products to help companies achieve green and efficient production. If you want to buy a feeding equipment that can meet your production needs and reduce the impact of noise, please contact us and we will provide you with a professional solution.