On the automated production line, the precise feeding of bottle caps is a seemingly simple but very critical link. Every bottle cap must be sent to the subsequent equipment at the right position and time. A slight deviation may affect the efficiency of the entire assembly. At this time, cap vibrating bowl feeder comes on the scene - especially the cap Vibrating bowl feeder designed by us specifically for the bottle cap industry, which is simply the "rhythm master" on the assembly line.

Our cap vibrating bowl feeder is widely used in food packaging, pharmaceutical manufacturing, daily chemical products, beverage filling and other industries. Whether it is a mineral water bottle cap, a medicine bottle cap, a screw cap for skin care products, or a small plastic cap of a special shape, it can be easily identified, quickly sorted, and stably transported. Whether it is a round, square, lock, or anti-counterfeiting ring structure, it is no problem to give it to it. Many customers have reported one word after using flip top cap vibratory bowl feeder: worry-free.

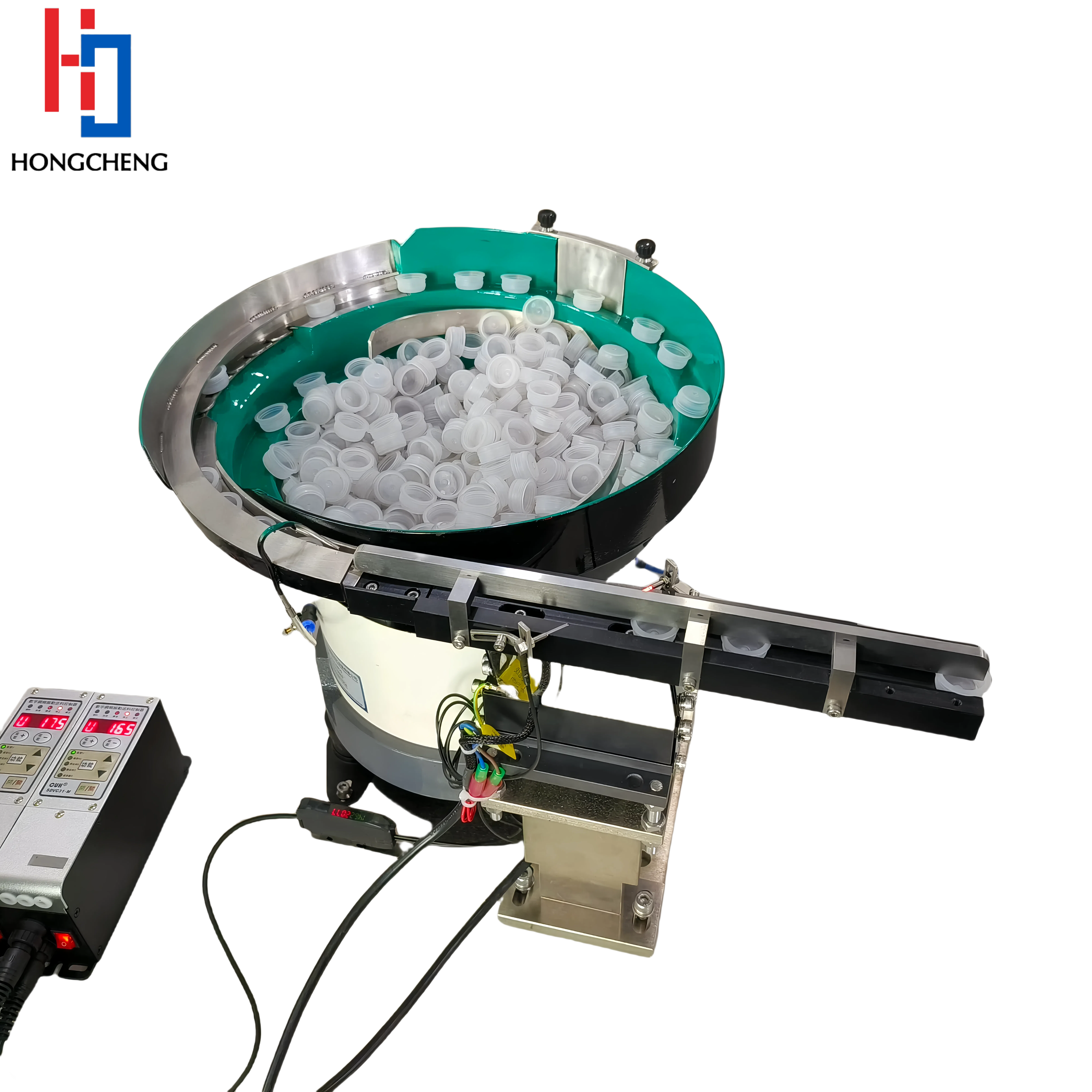

Cap vibrating bowl feedermay seem small in size, but its internal structure and debugging are very particular. The Flip Top Cap Vibratory Bowl Feeder we designed is a multi-spiral channel, which, combined with a high-frequency vibration drive, can deliver bottle caps stably, continuously, and without jamming. During the operation of the equipment, each bottle cap is transported forward in an orderly manner as if it has been arranged, just like the "train carriage" of the automated production line, with an orderly rhythm.

Our factory has multiple CNC machining centers, precision lathes, wire cutting, laser cutting and other high-precision equipment, and all bowls are processed independently. For the shapes and materials of bottle caps in different industries, we can provide customized track design and feeding solutions, so that each flip top cap vibratory bowl feeder can truly "understand what you need". Our team has rich experience accumulation, and can respond efficiently from drawing design to physical debugging to help customers quickly put into production.

In order to meet the needs of customers for diversification and rapid delivery, we are also constantly expanding the factory, updating equipment, and introducing more advanced CNC molding machines and automatic frequency modulation control systems to make equipment adjustment more accurate and operation more stable. At present, we produce more than ten standard equipment per day, and customized projects can also be delivered within two weeks, greatly improving customer response speed.

We know that a small bottle cap also represents the accuracy and efficiency of the entire production line, so we don't care about every detail. If you are worried about feeding bottle caps, you might as well try our flip top cap vibratory bowl feeder. Welcome to contact us and discuss how to “feed” your bottle caps faster and more accurately!