On the mobile phone production line, how are tiny parts - screws, buckles, shell accessories, camera modules, metal springs, etc. - delivered to the assembly station accurately, efficiently and without error?

The china cast aluminum feeder bowls we produce is particularly suitable for the transportation of small and precise parts such as mobile phone parts. It has a stable structure, long service life, and can be customized according to the shape and material of different parts. Some parts carry static electricity, so we can match them with anti-static design; some mobile phone accessories require operation in a clean environment, and we can also configure dust-free covers and silent covers for customers to reduce operating noise and protect the workshop environment.

Although the role of china cast aluminum feeder bowls is simple, it is very critical. It sends a large number of bulk parts to the next process neatly and in the same direction through vibration, rotation and other methods. For example, the common card holder springs, small screws, metal buckles, battery cells, etc. in mobile phones, the traditional manual feeding method is not only inefficient, but also prone to errors. Using our china cast aluminum feeder bowls, not only is the feeding faster, but also reduces manual intervention.

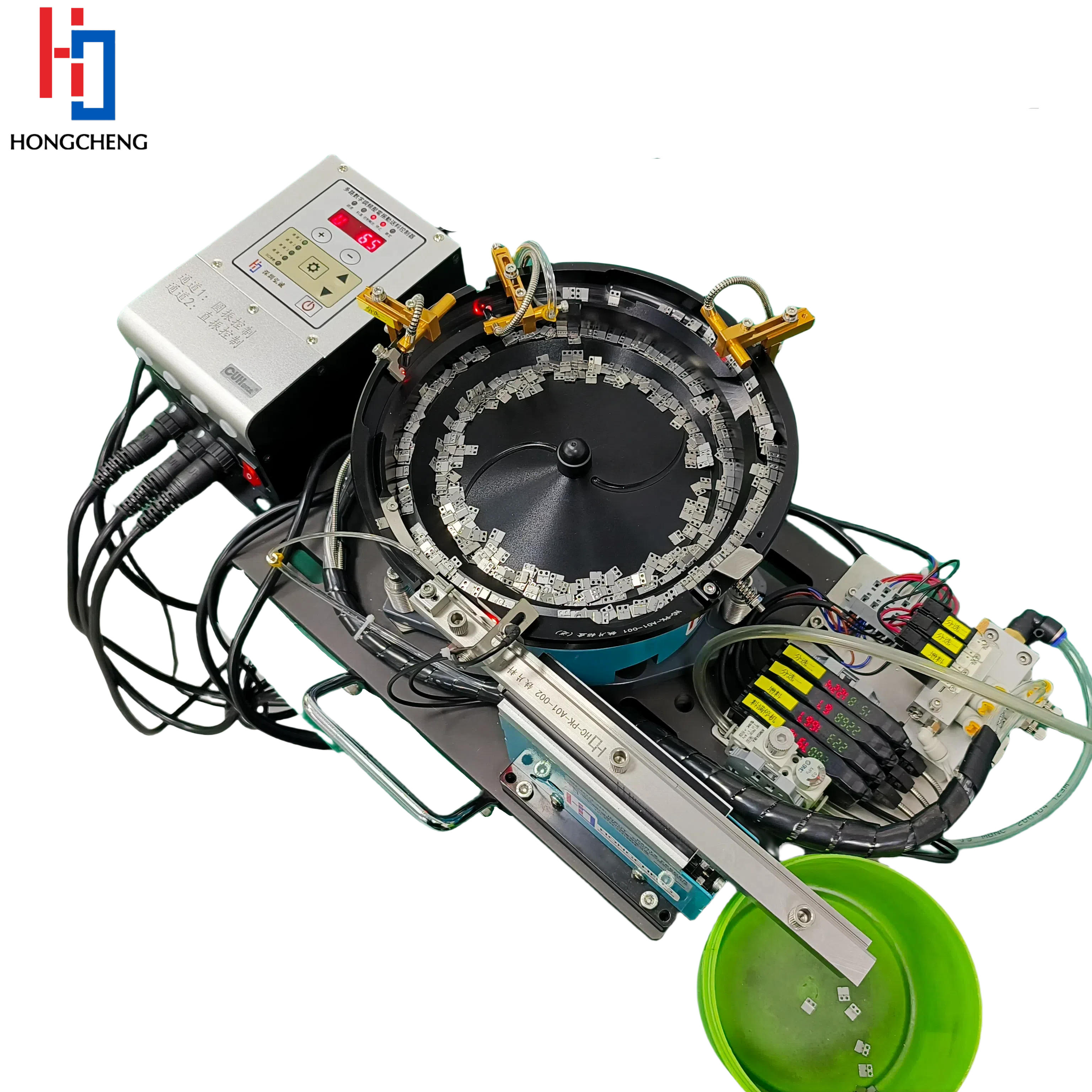

Our factory currently provides a domestic mobile phone manufacturer with multiple sets of cast aluminum vibratory feeder bowl, which are specially used for the delivery and loading of mobile phone metal parts such as cameras and screws. This cast aluminum vibratory feeder bowl is not only highly stable and wear-resistant, but also can maintain very low errors during high-speed operation. In addition, we have made special treatments in structural design, such as the inner wall angle, track width, and discharge speed are specially adjusted according to the customer's part structure to meet the various requirements of the customer's delivery production line.

Our non-standard customization capabilities are also a very big advantage. No matter how complex the shape of your parts is or how special the size is, our engineering team can design a special bowl structure and track design for you based on samples or drawings. Welcome to communicate and customize with drawings and samples. Our designers are on call at any time to create the most suitable loading solution for your product! if you are interest in our products, please contact us directly, we will give all our professional skills to you!