Which Bowl Feeder Vibrating is more impact-resistant? This actually depends on your specific usage scenario requirements, because aluminum and plastic bowl feeders each have their own advantages.

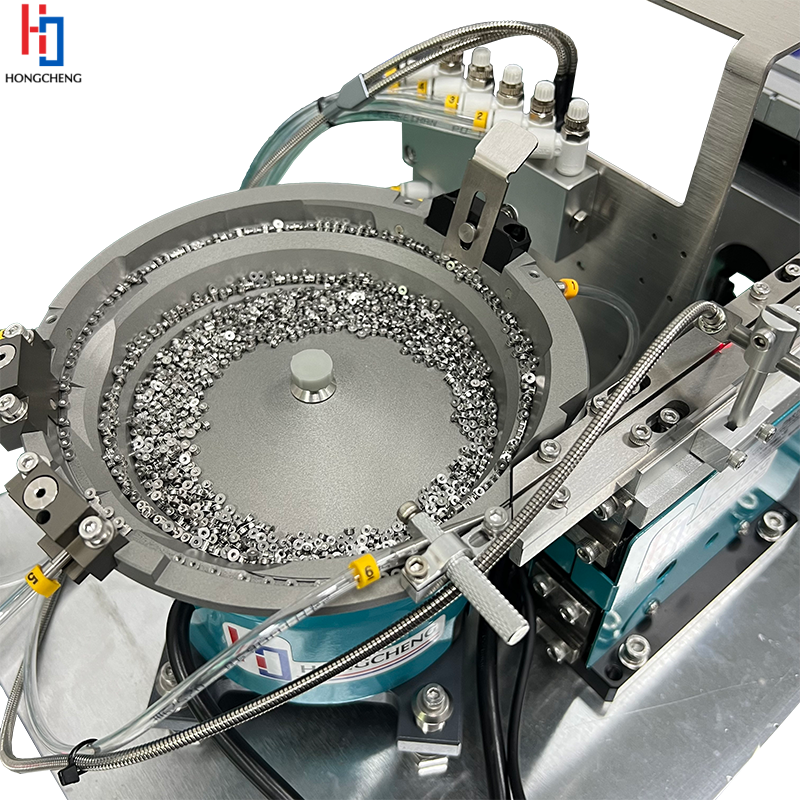

In daily industrial use, the impact resistance of your Bowl Feeder Vibrating is an important indicator of the stable operation of the equipment. The china cast aluminum feeder bowls we produce is made of high-quality aluminum alloy materials and has undergone high-precision CNC processing. The overall surface hardness is high and the structure is sturdy, which is very suitable for those high-frequency and high-intensity working environments. The china cast aluminum feeder bowls we produce is not only impact-resistant, but also wear-resistant and not easy to deform. It is particularly suitable for continuous conveying of metal parts.

The china vibrating bowl feeder for plastic we produce is made of industrial-grade engineering plastics, which has good flexibility and certain elasticity. When encountering strong external force impact, it can absorb part of the energy and avoid cracks in the bowl body due to severe impact. The advantage of china vibrating bowl feeder for plastic is that it is light and has relatively low noise during operation. It is suitable for transporting small and light parts.

In order to further improve the impact resistance, our china vibrating bowl feeder for plastic has also been optimized in design:

Bowl structure reinforcement: The bowl adopts an integrated thickening design to enhance durability;

Chassis shock absorption design: Whether it is an aluminum or plastic bowl, we can configure rubber cushions or suspension shock absorption systems;

Edge protection treatment: All bowl edges are rounded to avoid fragmentation or edge collapse during material transportation;

Non-standard customization options: We support personalized customization of different diameters, thicknesses, coatings and structures to meet the different requirements of customers.

Hongcheng not only has a professional R&D team, but also has a complete non-standard customization production system. Whether the customer needs a high-strength and impact-resistant aluminum alloy bowl or a lightweight and silent plastic bowl, we can perform one-to-one structural design and sample testing according to the specific size, weight, and operating environment of the material being transported.

At present, we have provided customized feeding systems for many industries such as automotive parts, electronic components, daily hardware, and medical consumables, which have been well received by customers. Our factory has recently introduced a number of high-precision processing equipment and testing systems, which has greatly improved production efficiency and has stricter quality control for every product shipped.

If you also need to use Bowl Feeder Vibrating, please contact us and tell us your requirements. We can design an Bowl Feeder Vibrating specifically for your product based on your production line and the actual items you deliver