In the production line of coffee bags, coffee bags with lanyard will make it difficult for traditional feeding equipment to operate. These slender lanyards are easy to tie knots or hang on the equipment, which affects the conveying efficiency. Through the optimized design of our centrifugal feeder for orienting coffee pods, the coffee bags with lanyard are kept in order during the conveying process, and the lanyard will not be entangled or stuck, making the entire feeding process smooth and efficient.

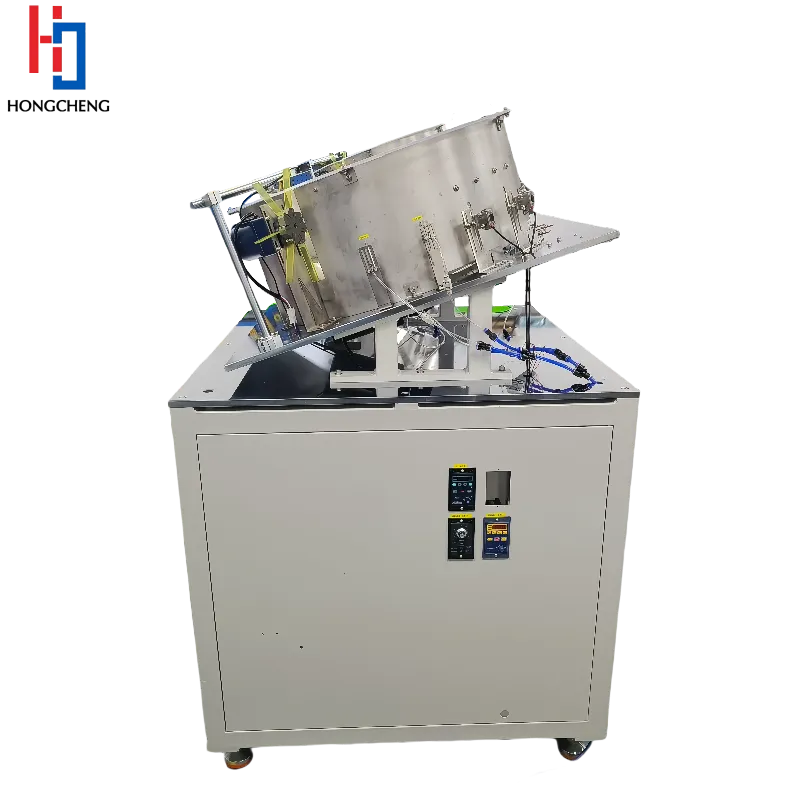

Ordinary vibrating disc feeders are easy to entangle the lanyard, and our centrifugal feeder for orienting coffee pods uses a unique design. The bottom turntable is responsible for separating the coffee bags, and the guide device is mainly responsible for combing the direction of the lanyard. Using advanced centrifugal feeding technology, the coffee bags with lanyard can be quickly arranged neatly and transported to the discharge port in a set direction. The centrifugal feeder for orienting coffee pods reduces manual intervention when running, making the production process smoother. According to tests, even if the lanyard with a length of more than 15 cm is processed, the system can still maintain stable transportation and will not get stuck.

Our centrifugal feeder for orienting coffee pods, which is specially made for coffee bags, has many innovative features. Through detection, the status of the lanyard can be identified, and the speed and tilt angle of the turntable can be adjusted. The guide groove uses composite materials to ensure the smooth delivery of centrifugal feeder for orienting coffee pods without scratching the surface of the product.

We can provide customized solutions for each customer. The length and material of the lanyard of different coffee bags may be different. Some lanyards are softer and easy to wrap, while others are harder and easy to cocked. We will adjust the performance feeders centrifugal feeder according to the actual samples, such as widening the channel for long lanyard coffee bags and adding soft cushion contact for hard lanyard coffee bags, so that each coffee bag with lanyard can find the most suitable delivery method to meet the customized needs of different customers.

Shenzhen Hongcheng Automation Equipment Co., Ltd. The factory has purchased advanced testing equipment. Each performance feeders centrifugal feeder must undergo rigorous testing before leaving the factory, and the samples provided by the customer are used for continuous operation verification. Our technical team will respond at any time, from pre-consultation to after-sales maintenance, so that the performance feeders centrifugal feeder has been in good working condition.

Nowadays, most coffee bags will be packed with lanyard. Our performance feeders centrifugal feeder can be transported smoothly. If you are interested in our performance feeders centrifugal feeder, please feel free to contact us. We will provide you with professional customized services and technology.