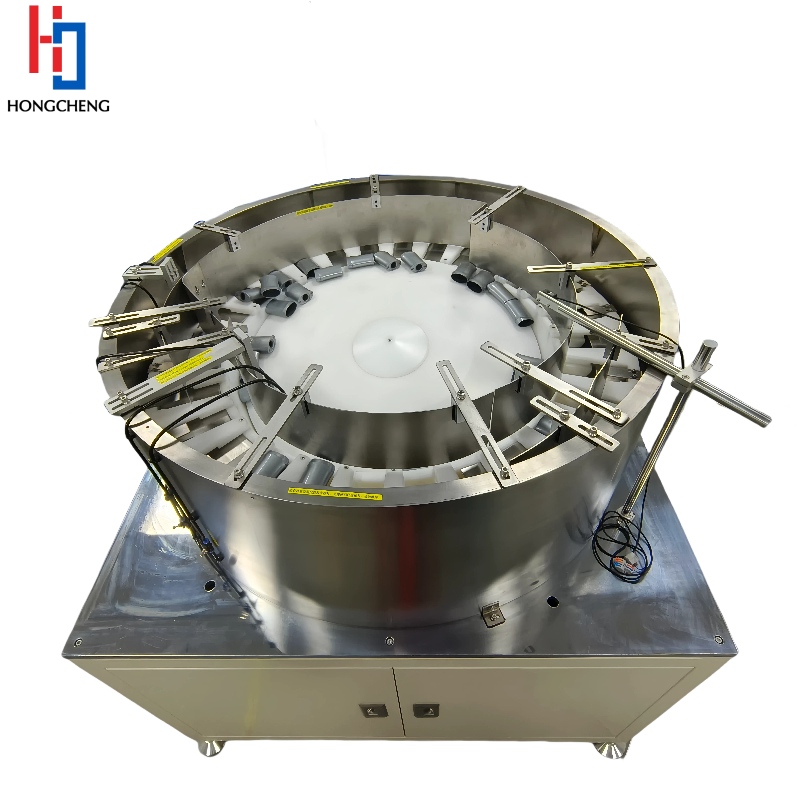

There are many different products involved in the assembly of cosmetic packaging production lines, such as bottle caps and bottles. How to load them quickly and accurately has always been a concern for cosmetic packaging manufacturers. The Cosmetics Centrifugal Feeder developed and produced by Hongcheng Factory can solve this problem very well. Glass Bottle Centrifugal Feeder has a compact structure, stable operation and high efficiency. It is very suitable for cosmetic containers of various sizes and materials, such as plastic bottle caps, glass bottles, lotion pump heads, etc.

The core principle of Glass Bottle Centrifugal Feeder is to automatically arrange the materials through centrifugal force and output them along the track. Although the whole process is very fast, it will not damage the surface of the product. It is very suitable for delicate and fragile cosmetic glass containers. Many customers come with samples, and we can find the right way to load them after testing. Whether it is a small-diameter round bottle cap or a special-shaped glass bottle, it can be stably transported to the next production equipment by adjusting the parameters.

We support non-standard customization. Each Glass Bottle Centrifugal Feeder can be designed according to the size, weight and material of the customer's product. We know that the cosmetics industry updates products quickly and customers' requirements are becoming more and more detailed. For example, if some customers need the entire line to cooperate with the visual inspection system, we will install an auxiliary interface on the Cosmetics Centrifugal Feeder. Some customers have limited space, so we can make the equipment smaller and provide modular design to facilitate the replacement of accessories.

In addition to the cosmetics industry, our Cosmetics Centrifugal Feeder is also widely used in pharmaceutical packaging, food containers, daily chemical products and other fields. For example, disposable small spray bottles, seasoning bottle caps, eye drops bottles, etc., we have made corresponding products. If you also encounter problems such as disordered bottle caps, slow manual feeding, and easy damage to transported products on the production line, you can come to our factory to test it in person. Many customers place orders directly after the test.

Hongcheng Factory has a complete design, processing, assembly and testing team. Each Cosmetics Centrifugal Feeder goes through multiple rounds of debugging before leaving the factory. We can cooperate with sample customization, drawing development, and remote technical guidance. You are also welcome to visit our factory to visit our production process. If it is not convenient to come, you can also watch the equipment online through video. We look forward to long-term cooperation with you!

📩 For quotes or custom designs, please contact:

Email: rubysun@szhcfeeders.com

📲 Phone: +86 18742554256