There are actually two common feeding devices in the feeding link of the automated production line: Bowl Feeder Vibrating and linear feeder. You may be confused about how to choose. Today, Hongcheng will take you to understand the differences between them and what kind of products they are suitable for from the perspective of a professional manufacturer.

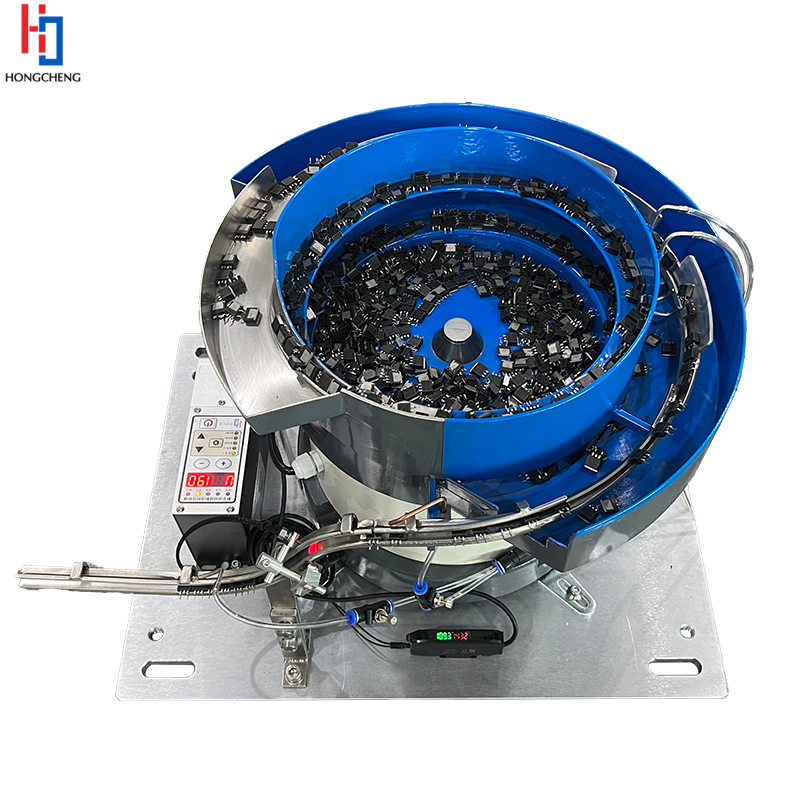

Hongcheng's main product is Bowl Feeder Vibrating, which is a very smart device that can be used in hardware, electronics, home appliances and other industries. The main advantage of Bowl Feeder Vibrating is that it has a compact structure and a small footprint. Even if your factory area is not large, you can easily place it. Bowl Feeder Vibrating can also accurately, continuously and automatically arrange small parts of various complex shapes in order. For example, screws, springs, buttons, gaskets... These small parts that are a headache can be easily handled by Vibratory Bowl Feeder.

Not long ago, we customized a set of Vibratory Bowl Feeder for transporting clothing buttons for a customer. The customer's buttons are of various styles and sizes. We perfectly helped the customer solve the problems of jamming and misdelivery by adjusting the track and optimizing the parameters.

So what is the difference between Vibratory Bowl Feeder and a linear feeder?

Different working methods: Vibratory Bowl Feeder automatically arranges parts through a disc-shaped vibration track, while the linear feeder is more like a straight "conveyor belt", which is mainly used to smoothly deliver the sorted parts.

Different use stages: Vibratory Bowl Feeder is responsible for sorting + feeding, and the linear feeder is mainly used for conveying.

Different scope of application: Bowl Feeder Vibrating is more suitable for products with small size and irregular shape, such as buttons, nails, springs, etc.; while the linear feeder is mostly used with the bowl type, which is suitable for processes with high requirements for conveying speed and stability.

In fact, the linear feeder is more like the "next step" of Bowl Feeder Vibrating. The parts arranged by the bowl feeder are transmitted to the next production line through the linear feeder. These two products are often used together.

Hongcheng supports various non-standard customizations. As long as you provide samples or drawings of parts, we can design suitable tracks, vibration solutions and control systems according to actual conditions. We have rich experience in non-standard design and processing equipment, which can meet various special requirements under complex working conditions. If you are also worried about how to automatically load materials, please contact us!