Can the adjustable speed centrifugal bowl feeder machinebe capable of precision conveying of electric motors and their parts? The centrifugal feeders in automation can transport electric motors. The professional adjustable speed centrifugal bowl feeder machine can not only efficiently transport various motor components, but also accurately locate and sort, providing an efficient transportation method for the motor, making the entire transportation process fast and stable.

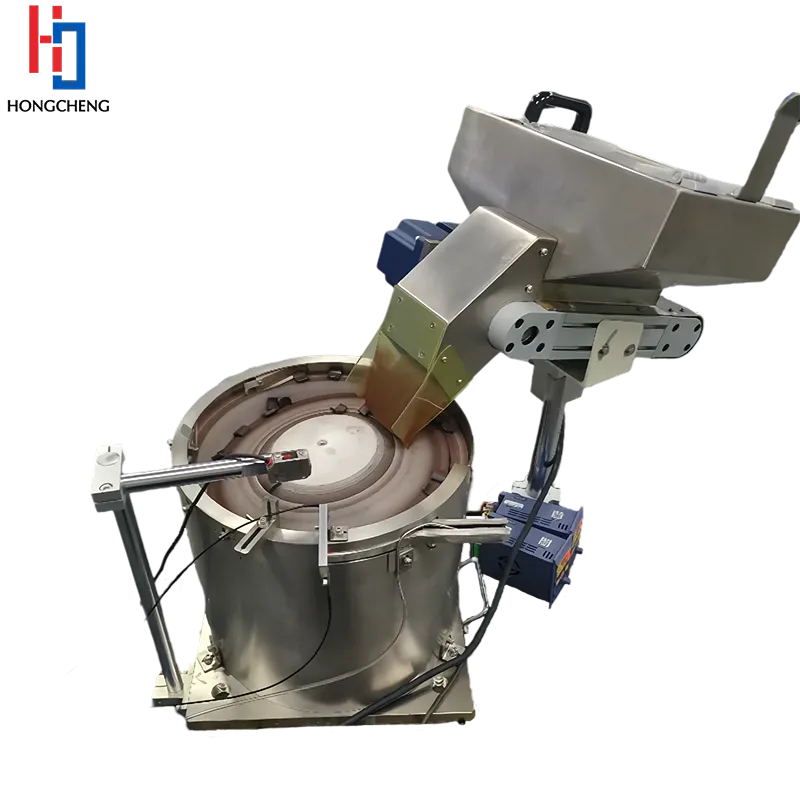

Our adjustable speed centrifugal bowl feeder machine uses an innovative design, suitable for handling complex parts of electric motors. The large rotor of a new energy vehicle motor, or the miniature gear set of a sweeping robot motor, the centrifugal feeders in automation can be delivered stably by adjusting the speed and tilt angle. For motor parts of different specifications, our system can distinguish parts of different diameters and accurately deliver them to the specified location. The conveying capacity of the adjustable speed centrifugal bowl feeder machine improves the efficiency of the motor assembly line a lot.

Our adjustable speed centrifugal bowl feeder machine has a speed control system that can automatically adjust the centrifugal force according to the weight of the parts, so that very light miniature brushes can also be transported smoothly. For special-shaped motor parts, such as special-shaped stator blades or rotors with bushings, we provide customized track and fixture designs so that each part can correctly enter the next work link.

We have built professional equipment production lines and high-precision machining centers. Each of our centrifugal feeders in automation is continuously tested before leaving the factory to simulate different working conditions in actual production. We also pay special attention to the design of the equipment. The key components are made of aviation-grade materials, which enables centrifugal feeders in automation to maintain stable performance under long-term high-load operation. For the motor industry, which has special requirements for cleanliness, we have also developed dust-proof and anti-static equipment to meet your needs.

We provide customized services. Different motors may have different sizes, weights, and shapes. For example, some motor housings have bumps, some are relatively large in size, and some are more fragile in material. We will adjust centrifugal feeders in automation according to customer requirements and specific circumstances. If the motor is afraid of scratches, we will add a protective layer to the bowl wall; if the motor has a special shape, we will modify the design of the discharge port so that the motor can pass smoothly. Our customized centrifugal feeders in automation can protect the motor well and improve production efficiency.

Shenzhen Hongcheng Automation Equipment Co., Ltd. will continue to develop and research better centrifugal feeding equipment. If you are interested in our centrifugal feeders in automation, please feel free to contact us. We will provide you with a suitable feeding plan.