Introduction of vibratory bowl feeders for automated assembly:

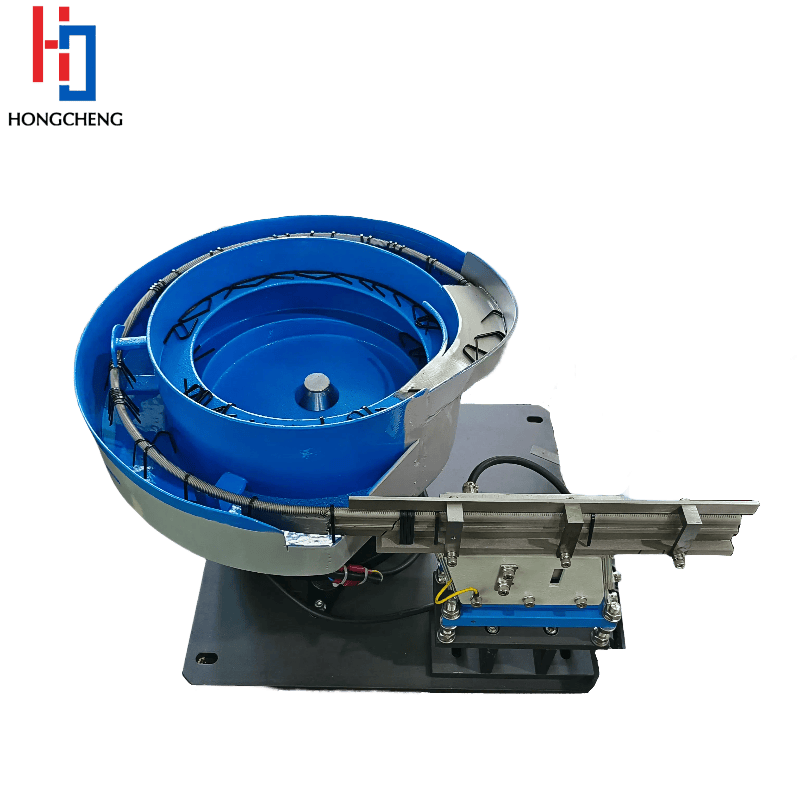

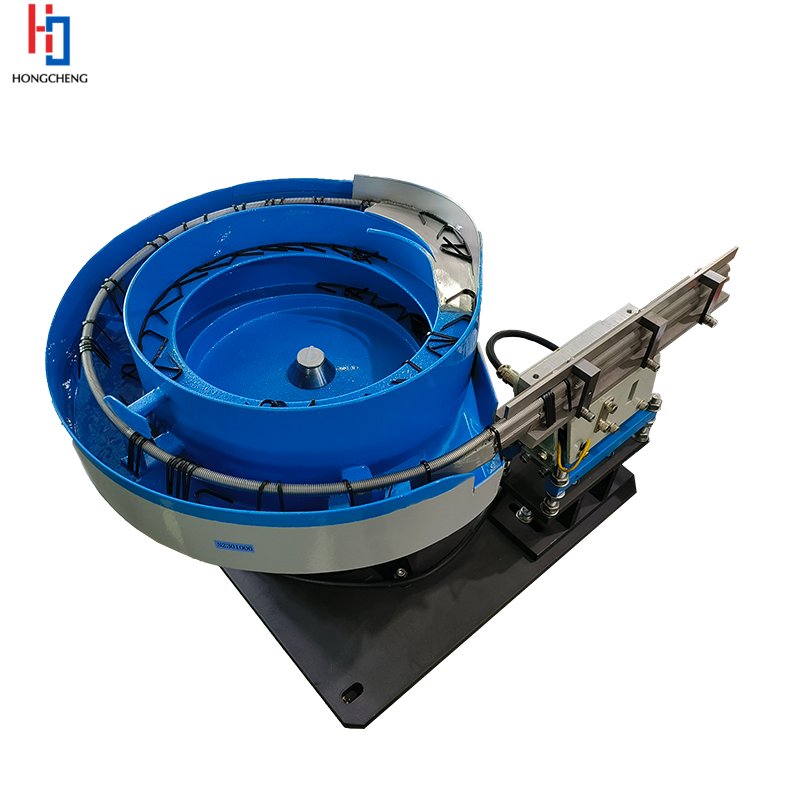

Vibration feeder bowl for connectors, also known as vibration plates, is a kind of mechanical equipment used in industrial automation connectors. Vibrating bowl auto bowl feeder for connectors mainly arranges scattered small parts in an orderly manner and transports them to designated locations, providing prepared small parts for assembly, testing, packaging and other processes.

Features of vibration feeder bowl for connectors:

1. The design of vibratory bowl feeders for automated assembly is compact and occupies a small space.

2. Vibration feeder bowl for connectors can be used in environments with different temperatures to ensure that industrial automation connectors can be transported smoothly in different environments.

3. We can provide customers with customized services for vibrating bowl auto bowl feeder for connectors.

Working principle of vibration feeder bowl for connectors:

When the pulse electromagnet of vibrating bowl auto bowl feeder for connectors is energized, it will periodically generate magnetic force, causing the hopper to vibrate in the vertical direction. The tilted spring sheet converts the vertical vibration into the torsional vibration of the hopper around the vertical axis. The industrial automation connector parts will be placed in the hopper of the vibration feeder bowl for connectors and start to move on the spiral track due to the influence of vibration. During the movement, the industrial automatic connector parts will continue to roll and move. After the directional arrangement is achieved, they will pass through the track smoothly and continue to be transported upward to the next process.

Why does the material pile up or jam in vibratory bowl feeders for automated assembly?

During the feeding process, industrial automation connectors May pile up or get stuck in the track of the vibration feeder bowl for connectors, causing the feeding to slow down or even stop. This situation generally occurs when the part has a complex shape, uneven size or unreasonable track design. It May be that the track width or depth of the vibrating bowl auto bowl feeder for connectors is not appropriate, and the parts will be easily stuck. Or there is too much material, and the feeding track will become blocked. It is also possible that the material direction is incorrect, resulting in unsmooth feeding. If this happens, we need to properly adjust the track width and angle of the vibratory bowl feeders for automated assembly so that the parts can pass smoothly. Do not pour too much material at one time to keep the feeding channel unobstructed. Use a guide device or sorting mechanism to allow the parts to be correctly arranged before entering the feeding track.

Company profile:

The company has an experienced technical team that focuses on the research and development and optimization of automation equipment. Our vibratory bowl adopts a unique design that can adapt to parts of different specifications to ensure smooth and accurate feeding. The main products include automatic feeding vibratory bowls, automatic feeding bins, precision aluminum trays, flexible platforms, centrifugal equipment, etc.