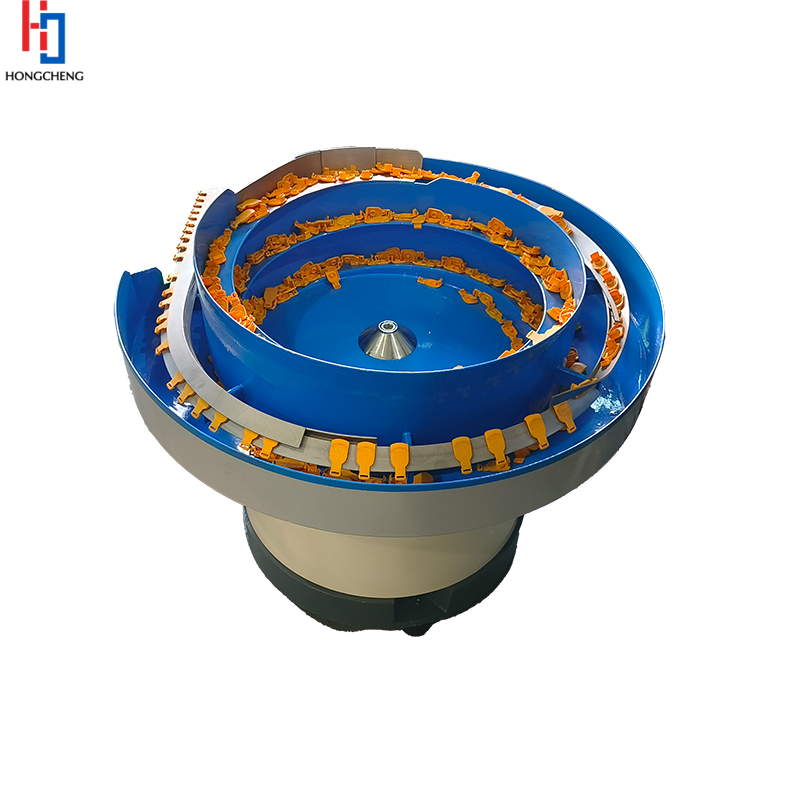

Introduction of cap vibrating bowl feeder:

Cap vibrating bowl feeder is the most common part feeding device used for feeding components in industrial assembly automation applications. Our vibratory plate bowl feeder is designed specifically for the plastics industry and is used to convey plastic products. Flip top cap vibratory bowl feeder is stable and durable, and is also suitable for oher mechanical and industrial equipment fields.

Advantages of cap vibrating bowl feeder:

1. Vibratory feeder bowl for plastic housings uses piezoelectric chips as the driving source. Cap vibrating bowl feeder reduces mechanical transmission components and simplifies the workflow.

2. Cap vibrating bowl feeder generates low noise when working in the low frequency band or ultrasonic band, which is suitable for noise-sensitive environments.

3. The cap bowl feeder has a simple structure, which simplifies the installation and maintenance process.

How does vibratory plate bowl feeder work?

Our flip top cap vibratory bowl feeder comes in a variety of shapes and sizes, including an outfeed accumulation track. Vibratory plate bowl feeder is primarily used to transfer parts and unload into assembly machines. The vibratory feeder bowl for plastic housings have a drive unit that is either electromagnetic or pneumatic. Vibratory feeder bowl for plastic housings vibrate the bowl feeder, forcing the parts up a circular, inclined track. The tracks on the cap bowl feeder are designed to sort and locate parts, keeping them in a consistent, repeatable position. The length, width and depth of the track can be adapted to the application and the shape and size of the parts. Depending on the shape, size and material of the parts, the cap bowl feeder uses a special track coating that increases traction, reduces product damage and reduces noise levels. The variable speed control box on the vibratory plate bowl feeder controls the vibration of the bowl feeder and uses sensors to stop the flow of parts to the outfeed track.

How to install a vibratory plate bowl feeder?

When installing a flip top cap vibratory bowl feeder, first check that the entire machine and accessories are consistent with the packing list, and then check if the hardware of each part of the main machine is loose. Be sure to install the vibration reduction components in the corresponding position. When adjusting the height of the vibrating bowl, fix the base on the fixed plate or bracket. When connecting the equipment at the outlet of the vibrating bowl, leave an appropriate gap to avoid affecting the normal operation of the vibrating bowl. Connect the electrical plug of the vibrating bowl with the electrical control box, turn on the power, turn on the switch, slowly turn the potentiometer, and adjust to the required feeding quantity.

FAQ:

1. What types of components can flip top cap vibratory bowl feeder feed?

Vibratory feeder bowl for plastic housings can provide caps, screws, bolts, nuts, seals, springs, medical parts, molded plastics, etc.

2. What is the difference between bowl, centrifugal or pneumatic feeding systems?

Vibrating bowl feeder for plastic use vibration technology to move parts; centrifugal feeders use rotating disks to generate centrifugal force for gentle handling and high output rates; pneumatic feeders use air motors instead of electromagnetic coils, mainly used in corrosive and explosive environments.

3. Which industries have you provided automation solutions for cap bowl feeders?

We have provided services to many different industries (automotive, electronics, plastics) about vibratory feeder bowl for plastic housings.

About us:

The company's main products include: automatic feeding vibration plate, automatic feeding bin, linear feeder, electronic control, vibration platform, soundproof cover, vertical vibrator, precision aluminum plate, flexible platform, centrifugal and other products.