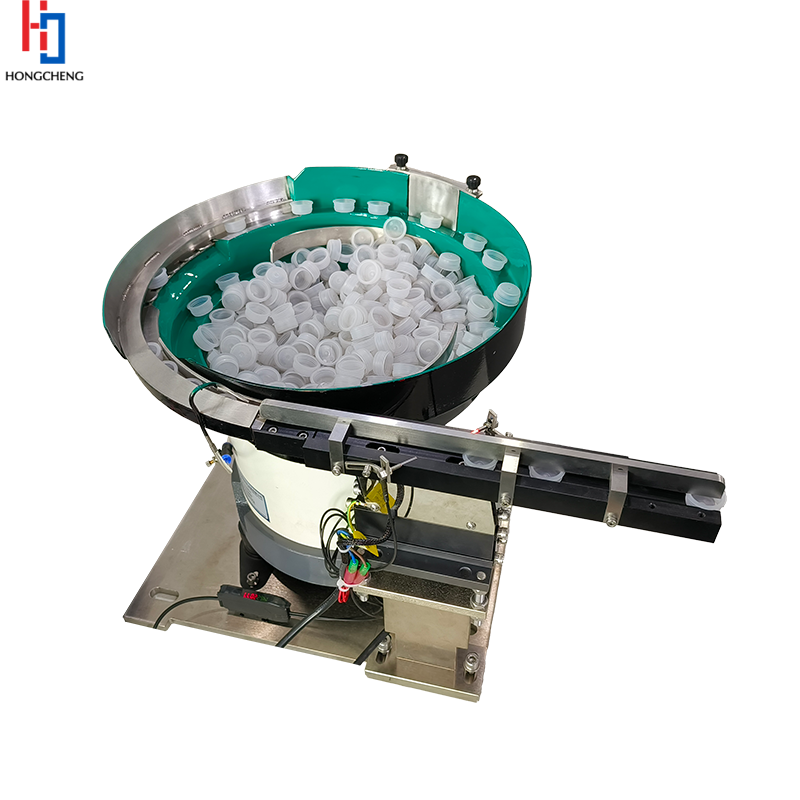

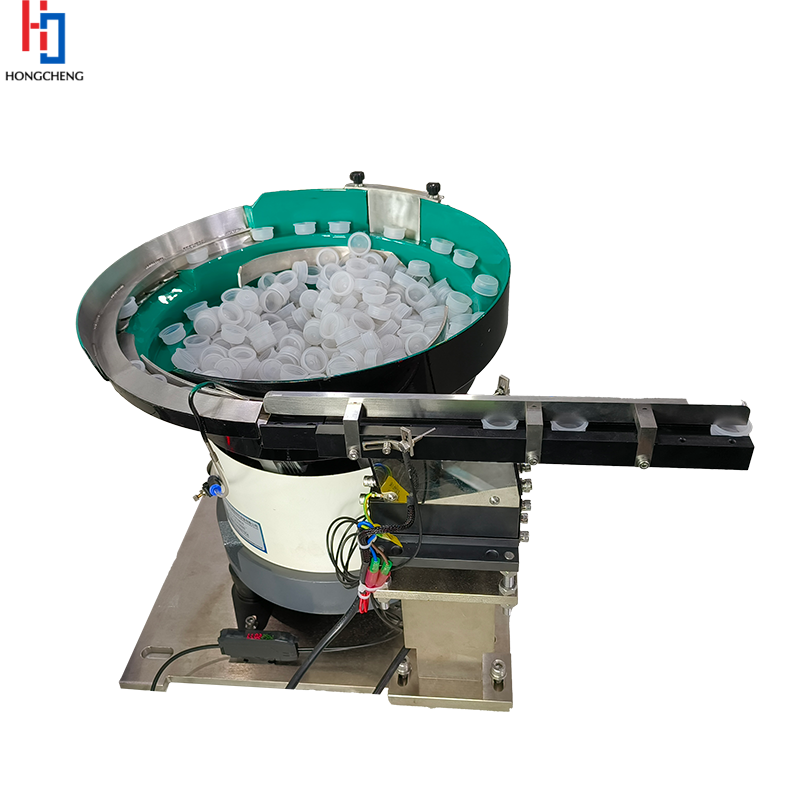

Product introduction:

Our automatic vibrating system bottle cap is designed for milk bottle production lines and can accurately transport milk bottles from one place to another. Whether it is bottle assembly, cleaning, handling, or sorting and conveying on an automated production line, our bottle cap feeder vibratory can handle it, which can not only improve production efficiency but also reduce labor costs.

How to choose the automatic vibrating system bottle cap?

When choosing the bottle cap feeder vibratory, you can choose a feeder with the appropriate capacity and delivery speed according to the bottle specifications and production rate of the production line. If there are special size requirements, we can also provide customized services. In addition, we should also look at the degree of automation of the vibratory feeder system for plastic baby bottle caps, which can not only reduce the error rate, but also reduce labor costs. Looking at the material of the automatic vibrating system bottle cap, we choose high-strength materials, which are more durable than general products.

How to optimize the bottle cap feeder vibratory?

During use, the motor control of the vibratory feeder system for plastic baby bottle caps can be accurately controlled by frequency conversion speed regulation, phase and amplitude adjustment. In addition, we can also regularly check and maintain whether the motor is in good working condition. According to production needs, we can adjust the trough angle, height and other parameters of the vibrating feeder, change the material conveying direction and speed, and meet different production requirements. At the same time, the various components of the automatic vibrating system bottle cap should be regularly inspected and maintained.

Common problems and solutions:

During product use, there are generally problems with bottle jamming or unsmooth conveying, because the vibration setting of the vibratory feeder system for plastic baby bottle caps is improper or there are obstacles in the conveying channel. We can first check the vibration system of the automatic vibrating system bottle cap to see if the vibration frequency and intensity are suitable for the size of the bottle and clear the obstacles in the conveying channel. When the bottle cap feeder vibratory makes abnormal noise, it may be that some parts in the equipment are loose or damaged. We need to check whether the screws and components inside the equipment are loose or worn, and those that are seriously damaged should be replaced in time.When we find that the feeding speed of the vibratory feeder system for plastic baby bottle caps is slow, the motor or drive system may be faulty. Check the connection line of the motor to see if it is loose and whether the motor can work normally, and contact the maintenance personnel in time to check the drive system.

How to maintain the automatic vibrating system bottle cap?

In the daily use of the bottle cap feeder vibratory, in order to extend the service life of the vibratory feeder system for plastic baby bottle caps, we need to regularly clean the bowl and conveying channel of the automatic vibrating system bottle cap to ensure that there is no dust, dirt or bottle residue, so as to ensure normal operation in the future. The vibration system of the bottle cap feeder vibratory should also be checked regularly to see if the vibration frequency and intensity are set correctly. In order to reduce friction, regularly check the rotating parts of the vibratory feeder system for plastic baby bottle caps, lubricate them appropriately, and ensure that screws, fasteners and other parts are not loose.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for automatic feeding systems (vibration plates). We can provide you with a series of products such as automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic controls, vibration platforms, soundproof covers, vertical vibrators, precision aluminum plates, flexible platforms, centrifuges, etc. You are welcome to consult.