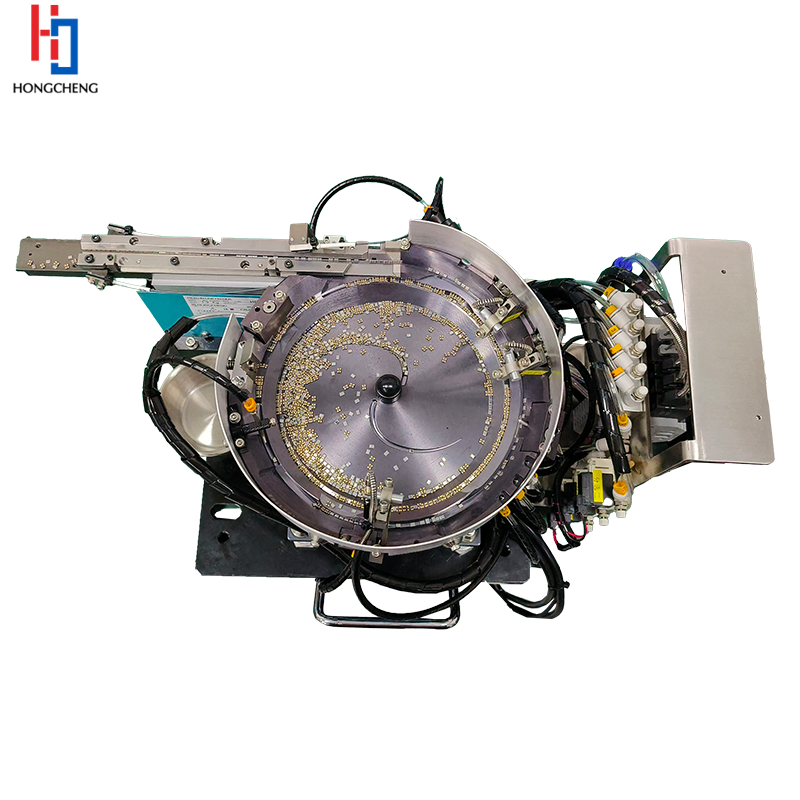

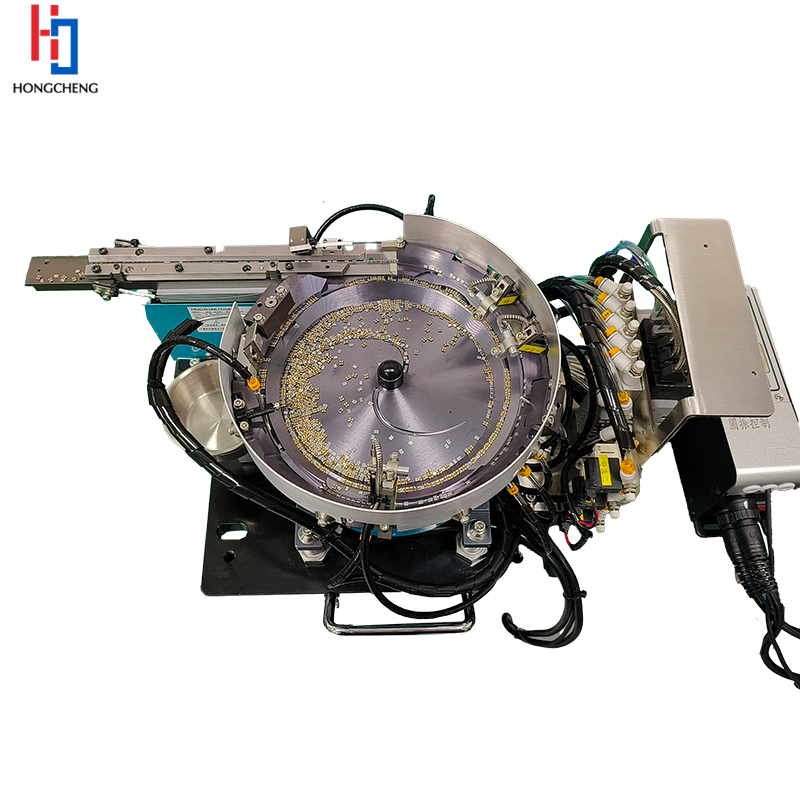

Product introduction:

Feeder bowl systems for electronic components is an automated electronic component feeding device that can arrange and transport electronic components to the next production line in an orderly manner. Feeder bowl systems for electronic components mainly consists of a vibrating plate part and a feeding part: The vibrating plate continuously vibrates to make the electronic components in the bowl spiral up along the track. During the rising process, they are screened and changed in posture by the track, and finally transported in a unified state.

Installation of vibrating plate:

When installing the vibratory bowl feeder for precision components, first ensure that the vibration reduction element is installed in the correct position. After adjusting the height and level of the vibrating plate, fix the base on the bracket. Ensure that the installation is stable to ensure that the electronic components can be transported smoothly. During installation, it should be noted that a gap should be left between the vibrating plate outlet and the connecting equipment to avoid affecting the normal operation of the vibratory bowl feeder for precision components. Finally, connect the electrical control box and the vibrating plate plug, turn on the switch after power on, and slowly adjust the potentiometer to the required feeding amount. After the installation is completed, the electronic components can be directly used for transmission. Before starting the machine, it should be noted that the potentiometer should be adjusted to the lowest level to prevent damage to the thyristor.

FAQ:

1. How small can vibratory feeders for electronic components handle?

A: Vibratory feeders for electronic components can handle micro components as small as 0.5mm. Customized tracks and precision vibration control ensure accurate delivery and positioning of tiny components.

2. How do Feeder Bowl Systems for Electronic Components prevent static electricity from damaging electronic components?

A: Feeder Bowl Systems for Electronic Components are made of anti-static materials (such as stainless steel or special coatings) and are equipped with a grounding design to effectively eliminate static electricity accumulation and protect sensitive electronic components from static electricity damage.

What electronic components can vibratory bowl feeder for precision components be used for?

Vibratory feeders for electronic components are applicable to components including but not limited to:

1.Micro components: Such as resistors, capacitors, inductors, etc.

2.Semiconductor devices: Such as diodes, transistors, integrated circuits, etc.

3.Connectors: Such as pin headers, female headers, USB interfaces, etc.

4.Precision components: Such as micro switches, relays, sensors, etc.

5.Packaged components: Such as qfn, qfp, bga and other packaged chips.

6.Other small components: Such as leds, crystal oscillators, fuses, etc.

About us:

Shenzhen hongcheng automation equipment co., ltd. Is a high-tech enterprise focusing on the research and development, production and sales of non-standard automation equipment, and is committed to providing customers with efficient, reliable and customized automation solutions. The company's main products are various types of feed trays, and it has accumulated rich experience in the research and development, sales and service of related fields. Adhere to customer needs as the core, continue to innovate, and improve product quality and service standards.