Product introduction of Centrifugal Feeder System:

Centrifugal Feeder System is an automatic feeding equipment designed for the automotive manufacturing industry. It uses advanced centrifugal technology to efficiently and accurately feed various automotive parts into the production line. Centrifugal feeder is suitable for various types of parts, such as screws, nuts, washers and other small parts, ensuring automatic feeding and precise orientation of parts during the production process. The Centrifugal feeder we produce can improve the efficiency and accuracy of automotive parts production and achieve more stable automated production.

What is Centrifugal feeder ?

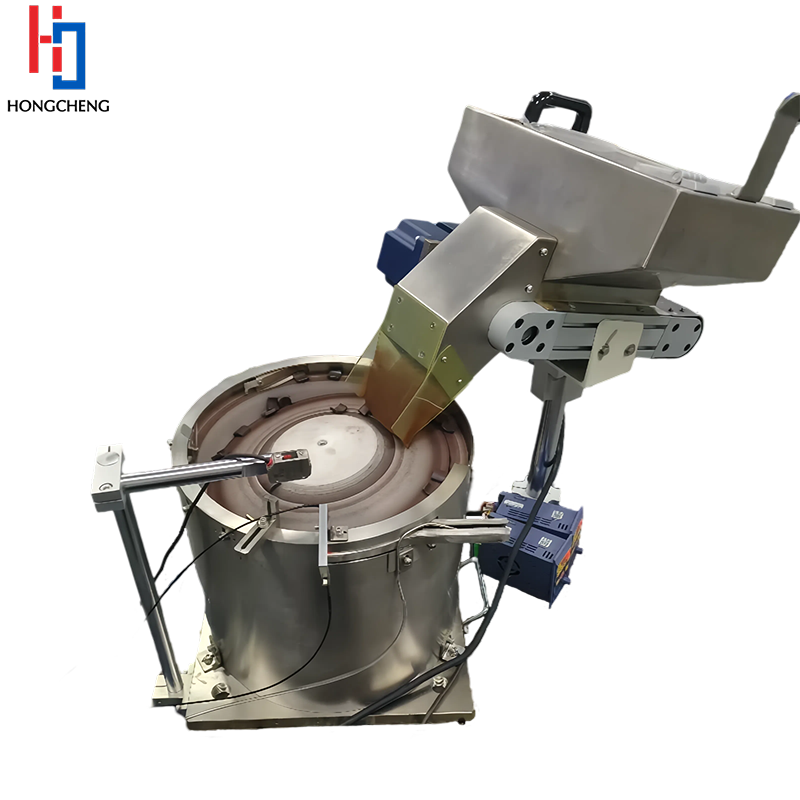

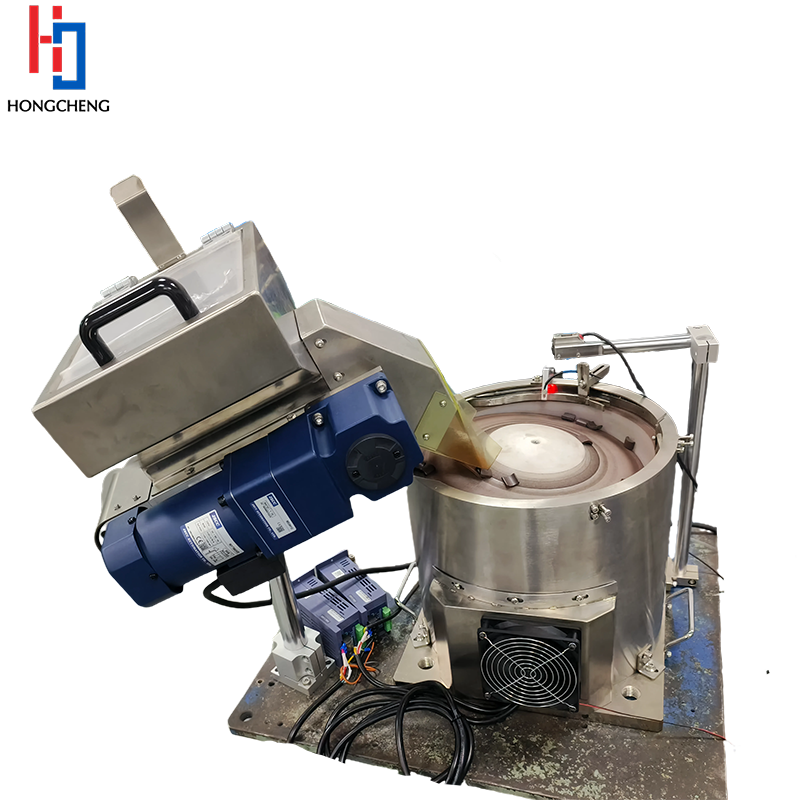

Centrifugal feeder is a feeding device that can be used to feed automotive parts efficiently and quickly while reducing the risk of part damage. Centrifugal feeder consists of a conical central drive rotor surrounded by a circular bowl wall. Centrifugal feeder system uses rotational force to spin and separate the conveyed automotive parts, which are rotated at high speed and pulled out of the bowl. Centrifugal feeder system is best suited for high-rate applications due to its low cycle times and is gentle on the parts.

How does centrifugal feeder work?

High feed rate centrifugal feeder system consists of a center disk mounted at an angle and a horizontally mounted auto parts feed bowl. Both components can rotate independently at variable speeds. The parts centrifugal feeding systems for the automotive industry produced by HONGCHENG can process up to 3,000 parts per minute. The working principle of parts centrifugal feeding systems for the automotive industry mainly relies on the control of centrifugal force and rotation speed. When auto parts are put into the feed bowl, the parts in the bowl begin to move along a circular trajectory as the bowl rotates. At this time, the rotation speed and angle of the feed bowl cooperate with the centrifugal disk to bring the parts to the raised edge of the centrifugal disk. Under the action of centrifugal force, the parts are evenly distributed on the edge of the high feed rate centrifugal feeder system, so that they can smoothly enter the next step of the assembly process.

Packaging and transportation of Centrifugal Feeder System:

Each parts centrifugal feeding systems for the automotive industry will undergo a strict quality inspection before leaving the factory, and will be packaged after confirmation. The packaging materials are high-strength wooden boxes and foam protective layers to prevent vibration and collision. The various components of parts centrifugal feeding systems for the automotive industry will be individually packaged and reinforced to ensure that they will not be damaged by any external factors during transportation. During transportation, all parts centrifugal feeding systems for the automotive Industrys will be tracked and managed to ensure real-time updates of logistics information, and customers can check the transportation status of the equipment at any time. Customers can unpack and install according to the packaging instructions. The installation process is simple and clear, and is equipped with a detailed operating manual and technical support. If you have any questions, our after-sales service team will provide full technical guidance to ensure that high feed rate centrifugal feeder system can be put into use smoothly.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. has always adhered to the business philosophy of "honesty, trustworthiness, unity and innovation", focusing on providing customers with efficient and reliable automation equipment. The bowl feeder, centrifugal feeder and other equipment we produce are widely used in machinery, electronics, food and other industries, and have become the preferred tools for automated production in many companies. We not only provide first-class products, but also provide comprehensive technical support and after-sales service, striving to create greater value for customers and promote industry development.