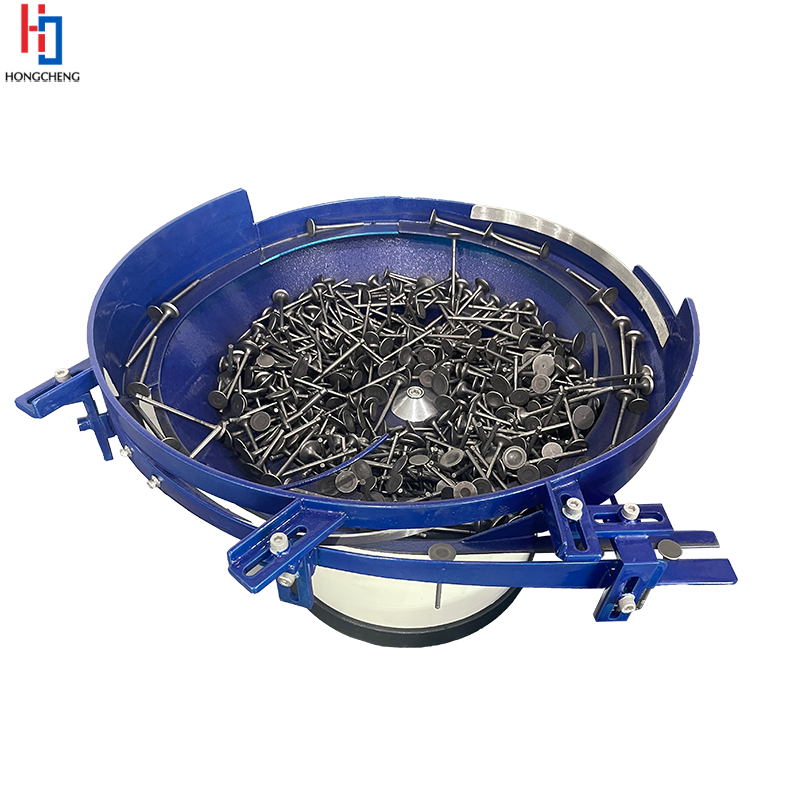

Product introduction:

Vibratory bowl feeders for the automotive sector are mainly used for valve delivery and assembly in the automotive manufacturing industry. They use vibration feeding to deliver messy automotive valves to the designated location in an orderly and orderly manner. Vibratory bowl feeder to feed engine valves are suitable for automotive valves of different specifications and are widely used in automotive parts production lines.

Product advantages:

1.Vibratory bowl feeders for the automotive sector can unify the direction of automotive valves during the delivery process, so that the valves can enter the next process safely and stably.

2.Vibratory bowl feeder to feed engine valves uses optimized vibration control technology to reduce operating noise and improve the overall working environment.

3.Vibratory bowl feeder orients small rubber parts adopts automatic operation, which not only reduces costs, but also reduces the error rate.

Working principle:

Vibratory bowl feeders for the automotive sector are mainly composed of vibration plates, controllers, bases and other parts. After the vibratory bowl feeder orients small rubber parts starts working, the controller drives the vibration plate to generate tiny vibrations, so that the car valve moves up along the preset track in the bowl. Through the reasonably designed track and vibration rhythm, the valves will be automatically sorted during the conveying process, so that their directions are unified, arranged in the set order, and finally conveyed to the specified position. The vibration source of the vibratory bowl feeder orients small rubber parts usually adopts electromagnetic vibrators or piezoelectric drive technology, which enables the equipment to accurately control the feeding speed. The track design of Vibratory bowl feeders for the automotive sector is also very important. Generally, a spiral ascending design is adopted, so that the parts can be smoothly conveyed upward without jumping out of the track due to excessive vibration.

How to use:

We first fix the feeder on a stable workbench and adjust the horizontal state of the equipment, then connect the power supply according to the instructions of the vibratory bowl feeder to feed engine valves, check whether the voltage matches, and check whether the power connector is firm to avoid abnormal operation of the vibratory bowl feeder orients small rubber parts due to poor contact.

Then adjust the amplitude, track inclination angle and other parameters according to different valve specifications, pour the car valve into the vibration bowl, start it, observe the operation, and make the feeding process smooth. If the valve is found to be stuck during the feeding process, the track angle or amplitude should be adjusted appropriately to avoid jamming.

Company profile:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for automatic feeding systems (vibration plates). The company's main products include: automatic feeding vibration plates, flexible platforms, centrifugal and other series of products. Our company's vibration plates and automation equipment are widely used in light industrial machinery, standard parts, connectors, bearings, connectors, batteries, medical equipment, cosmetics and food packaging machinery, semiconductors and testing, electronic precision products and other industries.