Introduction to automated assembly machines:

The loading and unloading system of connector assembly automation uses a combination of vibration plate and conveyor belt to realize the automatic feeding of connectors. The vibration plate can classify the connectors and neatly send them to the conveyor belt, which then sends the connectors to the assembly station. Connector assembly automation can be applied to industries such as automobiles and communications.

Advantages of connector assembly automation:

1. Precise and efficient connector assembly with automatic machines uses industrial-grade plc programming to realize the automatic operation and monitoring of equipment.

2. The automated assembly of Precise and efficient connector assembly with automatic machines can control the production process and improve product quality.

3. The design of connector assembly line for mini fakra 4p has been optimized to ensure stable production.

Composition of automated assembly machines:

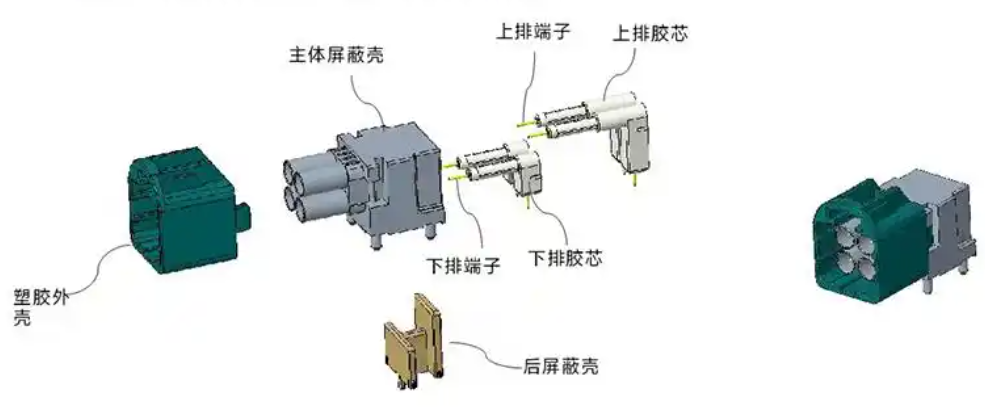

Automated assembly machines consists of fixtures, guide devices, detection systems, electrical systems, machine vision, etc. The fixtures of connector assembly automation are used to fix the connectors to ensure the stability of the connectors during the assembly process. The guide devices of automated assembly machines can guide the connectors to move along a predetermined trajectory during the assembly process. And our connector assembly line for mini fakra 4p uses a six-axis or four-axis robot to realize the automatic assembly of connectors. The light source, lens, image processing software, etc. In the detection system can detect the assembly quality, position, direction, spacing, etc. Of the connector in real time. The control system of connector assembly automation adopts industrial-grade plc programming, which can meet the needs of complex production environments. The power supply adopts a dual-circuit design, and the high resolution of the machine vision system can meet the requirements of high-precision assembly.

FAQ:

1. What are the main application industries of automatic fakra assembly machines?

Connector assembly automation is mainly used in automobile manufacturing, communication equipment, smart home, aerospace and other fields.

2. How does the automated assembly machine reduce the failure rate?

High-precision components, regular maintenance, and the use of suitable wires and connectors can be used.

3. Can the incorrectly installed fakra connector be automatically detected?

Yes, the connector assembly line for mini fakra 4p is equipped with a visual inspection system that can identify installation direction, misalignment and defects.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the research and development and sales of automatic feeding systems (vibration plates) and non-standard automation equipment, providing products such as automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems and vibration platforms. Our equipment is widely used in light industrial machinery, standard parts production, connector industry and bearing manufacturing.