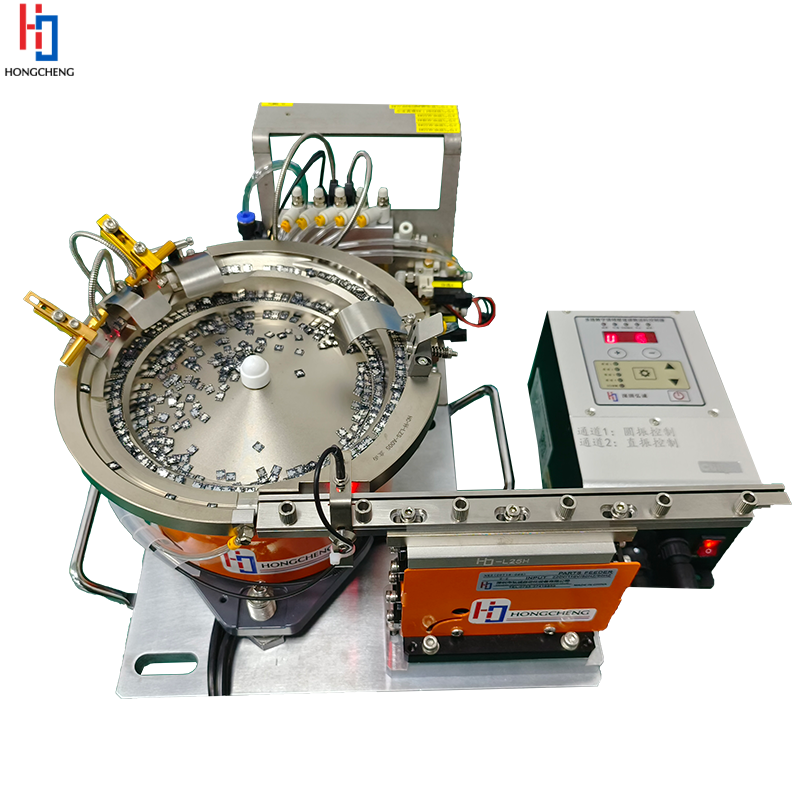

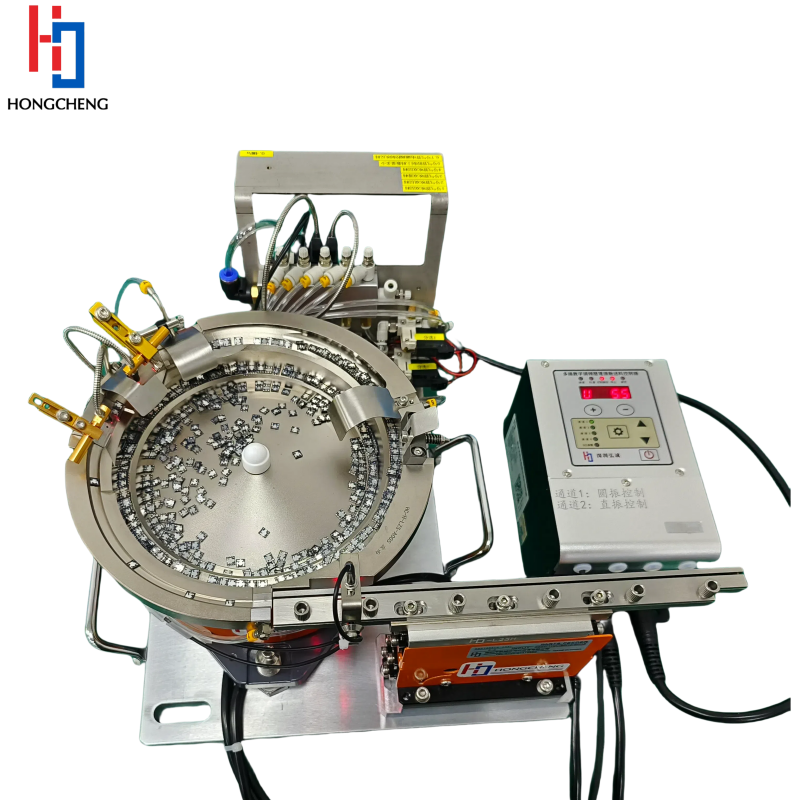

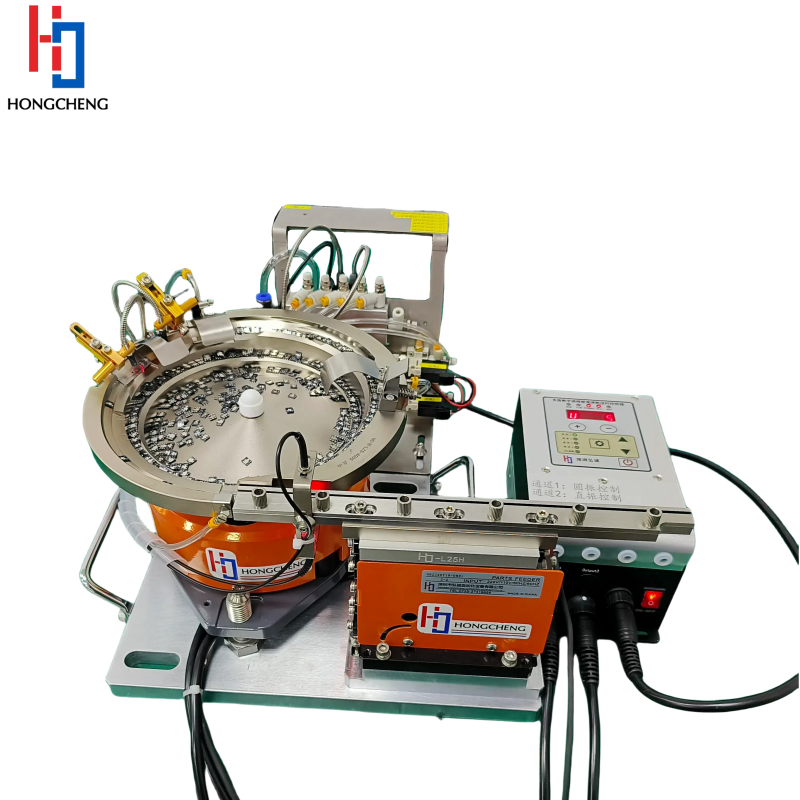

Product introduction of vibratory bowl feeder for automotive:

Vibratory bowl feeder for automotive is an efficient and accurate automobile parts conveying equipment. Aluminum automotive parts feeder generates vibrations through electromagnetic or mechanical means, and through track screening and adjustment, the automobile parts are accurately delivered to the next process. Aluminum automotive parts feeder is fully automated, which can effectively reduce manual operation errors and improve the efficiency of automobile parts transportation.

The main structure of aluminum automotive parts feeder:

Trough: A container used to hold and transport auto parts, usually in a U-shape or oval shape.

Spring: Plays a buffering and shock-absorbing role to ensure the stability of automatic vibratory bowl feeders for vehicle parts.

Vibrator: Generates vibration force to drive the transport of auto parts.

Controller: Adjusts the vibration frequency and amplitude.

Conveyor track: Adjusts the posture of auto parts and transports them to the next process.

What auto parts can automatic vibratory bowl feeders for vehicle parts transport:

Fasteners: such as screws, nuts, washers, bolts, etc.

Electronic and electrical appliances: such as sensors, connectors, circuit components, etc.

Seals: o-rings, rubber gaskets, dust covers, etc.

Precision small parts: such as springs, pins, bearing balls, etc.

Appearance parts: such as buttons, buckles, decorative parts, etc.

Product parameters of aluminum automotive parts feeder:

| Name | Hardware Vibratory Feeder Bowl | Specifications | Vibration |

| Chassis size | 300 | Weight | 10KG |

| Speed | 60/m | Disk diameter | 300mm |

| Voltage | AV220V (50-220 adjustable) | Controller type | FM controller |

| Interfacing method | 16mm aviation plug | Power | 50/w |

| Amplitude | 50Hz | Direct vibration extension length (mm) | 100-600 |

FAQ of automatic vibratory bowl feeders for vehicle parts:

Q: Is automatic vibratory bowl feeders for vehicle parts suitable for a variety of auto parts we produce?

A: Yes. Aluminum automotive parts feeder is highly flexible and can be used for different auto parts by changing the feed track and adjusting the vibration parameters. The feed track can be customized according to the shape, size and material of the auto parts.

Q: Will aluminum automotive parts feeder cause damage to precision auto parts during operation?

A: No. Vibratory bowl feeder for automotive uses intelligent vibration technology and flexible conveying design to transport auto parts smoothly and gently, effectively avoiding wear and tear during transportation. Moreover, the surface of aluminum material is smooth and will not scratch the surface of parts.

Q: Is vibratory bowl feeder for automotive complicated to maintain and clean?

A: Aluminum automotive parts feeder is made of aluminum material, which is smooth, not easy to accumulate dust, and easy to clean. With modular design, key components can be quickly disassembled and replaced, and daily maintenance costs are low.

Q: How should aluminum automotive parts feeder be maintained and cleaned?

A: We will provide detailed operation and maintenance guides to ensure that customers can easily master the use and maintenance methods of the equipment.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a high-tech enterprise focusing on the research and development, production and sales of non-standard automation equipment, and is committed to providing customers with efficient, reliable and customized automation solutions. The company's main products are various types of automatic vibratory bowl feeders for vehicle parts, which can be used for the transmission of different types of objects. It has accumulated rich experience in the research and development, sales and service of related fields. Adhere to customer needs as the core, continue to innovate, and improve product quality and service standards.