When many people first heard the name Centrifugal Feeder System, the images that may come to their mind are: laboratories, test tubes, high-speed rotation, white coats... But in fact, this centrifugal is also a very practical concept in factory automation, and it is actually related to the "throwing force" we learned in physics class when we were young.

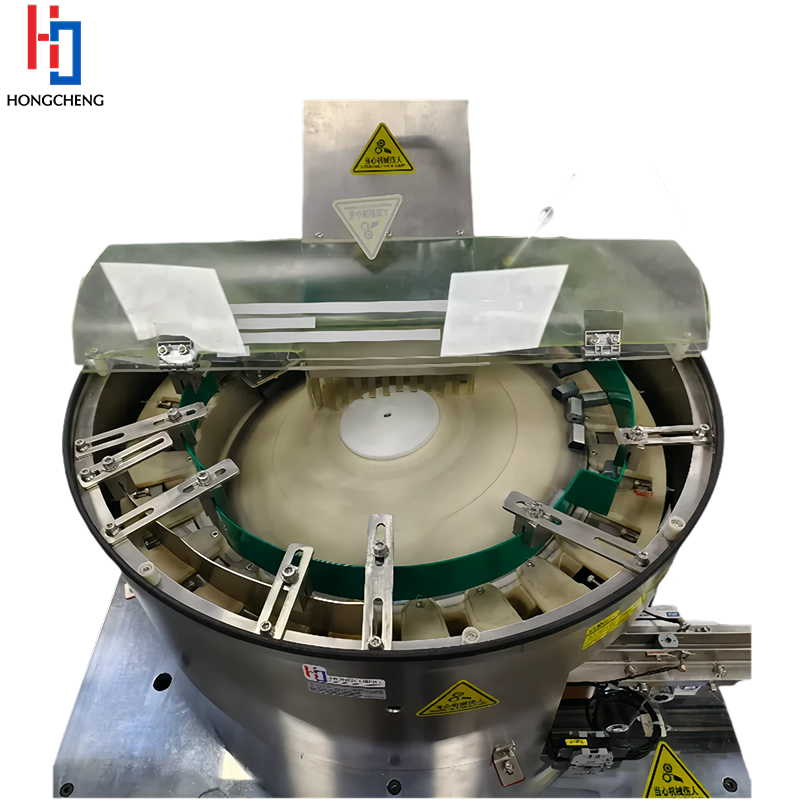

"Centrifugal" refers to an outward force generated by the inertia of an object in rotational motion. Simply put, when you ride a carousel and turn fast, you will unconsciously lean outward - this is the centrifugal force. And our Centrifugal Feeder System uses this principle to throw a bunch of messy small parts from the middle to the outer track, and by the way, sort out their positions and directions correctly and enter the correct track.

Doesn't it feel simple? It is just such a seemingly throwing process that solves the problems of part orientation, arrangement, and feeding. Compared with traditional vibration plates, Centrifugal Feeder System has faster processing speed and less noise, and is particularly friendly to light or regular-shaped workpieces.

Our Hongcheng factory has been focusing on non-standard automation equipment for many years. The independently developed Centrifugal Feeder system has been running stably in many industries: whether it is a small lid in the daily chemical industry, a straw cap in the medical industry, or a small part of hardware and electronics, it can be efficiently dealt with. The equipment runs smoothly, has excellent noise control, and has a long service life. The most important thing is that we can tailor exclusive Centrifugal Feeder System according to your product size, material and other requirements.

Our High Feed Rate Centrifugal Feeder System production line is equipped with advanced CNC machine tools, laser cutting equipment, and high-precision test benches. Each High Feed Rate Centrifugal Feeder System must pass dynamic balance tests and long-term operation tests to ensure that the equipment can be directly put into production when it is turned on at the customer's site. Not only is the quality excellent, but the service is also up to par. There are dedicated people to connect with pre-sales communication, drawing design, solution discussion, and after-sales response to ensure that you can use it smoothly.

If you are planning to make an automated transformation and don't want to get stuck in the feeding link, you might as well try our High Feed Rate Centrifugal Feeder System. It is not only smart and reliable, but also particularly suitable for "fast-paced and efficient" modern workshops. Moreover, our products are not only sold domestically, but also exported to many countries and regions. They have been evaluated by many customers as "saving trouble and saving money."

You may also wonder, will it get stuck at such a fast speed? Don't worry, our High Feed Rate Centrifugal Feeder System has an anti-jamming system and intelligent recognition mechanism to ensure stable and smooth operation. So next time you hear the word "centrifugal", don't just think of physics books or washing machines, think of those small parts in your factory, waiting to be put on the right track by High Feed Rate Centrifugal Feeder System and enter the next production line!