Many customers will ask when purchasing Vibratory Bowl Feeder: "Is there a big weight difference between aluminum Vibratory Bowl Feeder and ordinary Vibratory Bowl Feeder?" This question is indeed worth discussing. In fact, the weight difference of Bowl Feeder Vibrating mainly depends on the material, size and structural design. Compared with plastic materials, aluminum bowls are usually 30% to 50% heavier because of their higher density.

Aluminum Bowl Feeder Vibrating has good corrosion resistance, formability and appearance texture, and is very suitable for industries with high requirements for precision and cleanliness, such as electronics, medical, light industry, etc. Some people may worry whether aluminum Bowl Feeder Vibrating is not wear-resistant enough. In fact, in the design, we will harden the surface of aluminumBowl Feeder Vibrating or spray wear-resistant coating according to different workpiece materials and feeding frequency, so that its life is equivalent to that of steel bowls, and even more stable under certain working conditions.

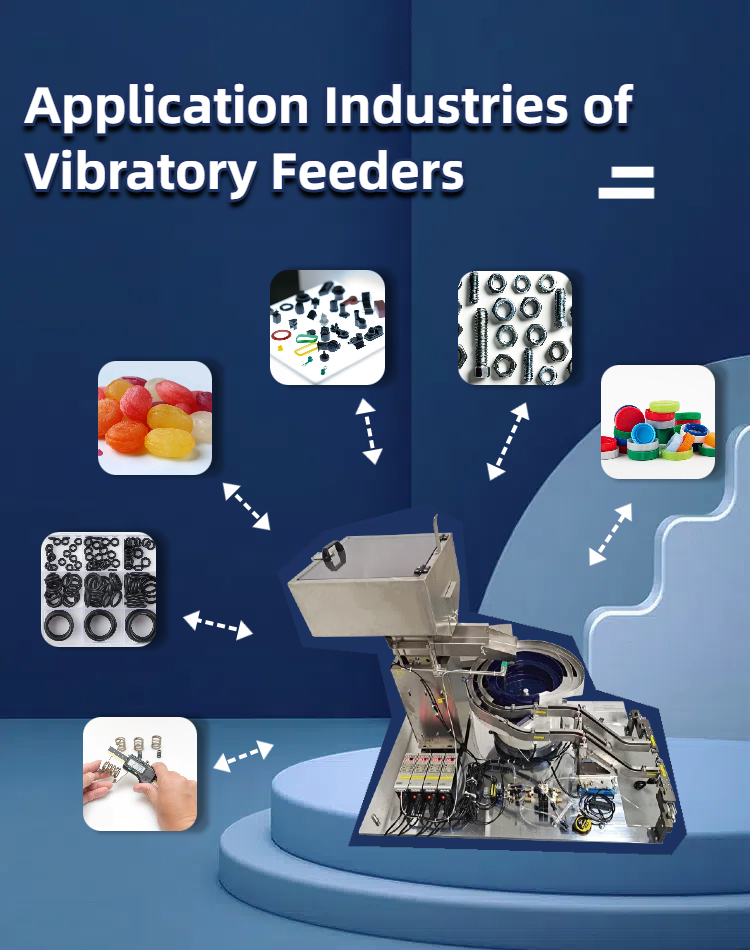

We are a manufacturer specializing in the design, research and development and production of Bowl Feeder Vibrating. Whether it is aluminum bowls, steel bowls, stainless steel bowls, or special-shaped tracks and multi-station discharge designs, we can customize solutions according to customer needs. Our Automatic Vibratory Bowl Feeder is widely used in various industries such as electronic components, hardware fasteners, plastic accessories, medical consumables, and automotive parts, and is suitable for high-speed assembly lines, inspection stations, and automatic packaging systems.

We are equipped with a complete set of work processes from design, proofing, testing to mass production. Customers provide samples, and our engineering team will perform three-dimensional modeling and simulate the feeding trajectory to match the bowl material and structural form according to the product shape and use environment. We will also consider the spatial dimensions, electrical interfaces, feeding speed and other parameters of the customer's equipment to ensure that the final delivered Automatic Vibratory Bowl Feeder can seamlessly connect to the production line. For some special structural products, our engineers can make innovative designs through multi-channel material distribution, intelligent control of the beat, etc., to make the feeding process smoother and more efficient.

In the production and manufacturing process, we have multiple CNC processing equipment, precision welding platforms, and professional assembly teams to ensure that every Automatic Vibratory Bowl Feeder meets high standards from parts to the whole machine. Before leaving the factory, the equipment will also undergo a long-term stable operation test, including continuous startup, feeding stability detection, noise testing, etc., to ensure that customers receive a truly "worry-free" device.

Our goal is not to sell a machine, but to solve the feeding problem of customers. We understand that automation is not as simple as "buying equipment", but also a set of systematic projects of "improving efficiency, reducing costs, and optimizing processes". Because of this, we not only attach importance to product design and production quality, but also have professional teams in pre-sales, sales, and after-sales to ensure that customers can get support in every link of the use process.

So, whether you are concerned about the weight, material, performance of Automatic Vibratory Bowl Feeder, or whether it can be matched with the existing system, we welcome you to communicate. We are willing to listen to your needs, willing to accompany you to test samples, and willing to tailor the "just right" automatic feeding equipment for you. Lighter, more stable, more accurate-maybe this is your ideal Bowl Feeder Vibrating.