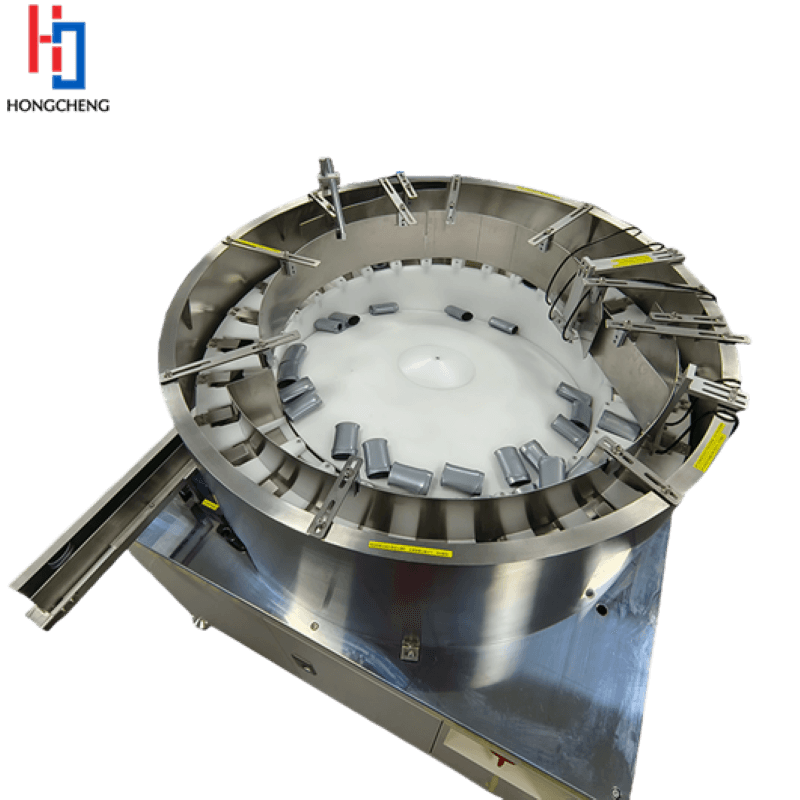

There are many shapes of cosmetic bottles: cylindrical essence bottles, square cream cans, slender perfume bottles, etc. Suitable cosmetics centrifugal feeder can handle cosmetic bottles of different shapes and sizes, whether it is round bottles, square bottles, fine-mouthed bottles, or wide-mouthed bottles, it can be delivered stably. So our cosmetics centrifugal feedercan be used in cosmetics production.

The advantage of cosmetics centrifugal feeder is that there is no need for manual contact during delivery. By controlling the centrifugal force, the collision and friction caused by the traditional conveyor belt are reduced during the conveying process of the bottle. This gentle treatment method is particularly suitable for fragile materials such as glass, perfume bottles with complex shapes or limited-edition packaging with decorations can be shipped intact.

Our cosmetics centrifugal feeder is fully automatic, and the conveying can be completed automatically after the discharge. For 30ml vials or 500ml large cans, the same equipment can complete the conveying task. When switching, you only need to select the corresponding program on the control panel, no mechanical adjustment is required. The preparation time for product replacement is shortened, and it is suitable for small batch production of multiple varieties. In some cosmetic factories, a production line has to change several bottle types. With our machines, there is no need to stop and adjust frequently, saving a lot of time.

There are special production lines in our workshop. Whether it is a small batch of orders or a large number of needs of the enterprise, we can deliver the goods on time. Each cosmetics centrifugal feeder will undergo multiple tests before leaving the factory to ensure that it remains in good condition when conveying different bottle shapes.

We can also do customized design. Some cosmetic bottles have special shapes, such as square bottles with edges and corners, and slender spray bottles. Ordinary equipment is not easy to transport, but we will adjust the centrifugal speed, channel width and curvature of the cosmetics centrifugal feeder according to the bottle sample provided by the customer. For example, a short cream bottle will widen the material channel and reduce the speed, and a slender essence bottle will be designed to fit the guide groove more closely, so that each bottle can move smoothly along the track.

Shenzhen Hongcheng Automation Equipment Co., Ltd. The main products include: vibratory bowl feeder, aluminum bowl feeder, cosmetics centrifugal feeder and other products. We have a perfect after-sales service system and excellent after-sales service personnel. We use advanced equipment to develop, design, difficult and high-quality bowl feeder systems and non-standard equipment to solve many of your automation problems. If you have any questions, please feel free to contact us!