Beyond Adhesion, Smooth Flow — Shenzhen Hongcheng Vibratory Feeder PTFE Coating Expertise

In modern industrial production, vibratory feeders are essential equipment for component feeding, ensuring high efficiency, accuracy, and continuous material flow. However, during feeding, parts often face challenges such as sticking, jamming, oil contamination, or surface wear, affecting both productivity and product quality. To address these issues, Shenzhen Hongcheng has applied advanced PTFE (Teflon) coating technology to its vibratory feeders, delivering professional, durable, and smooth material handling solutions.

Challenges in Vibratory Feeder Applications

Common problems in component feeding include:

Parts with oily or lubricated surfaces, causing sticking or halting in the feeding track

Rubber parts such as O-rings, easily caught in slots

Metal or plastic parts friction, leading to scratches or surface wear

Unstable material flow, increasing manual intervention and cleaning frequency

These issues reduce production efficiency and may compromise product quality, making enhanced feeder surface performance critical.

Advantages of PTFE Coating on Vibratory Feeders

The PTFE coating process used by Shenzhen Hongcheng addresses real-world feeding needs with multiple benefits:

Low friction

The PTFE surface dramatically reduces friction between parts and feeder channels. Even oily or soft rubber components can slide smoothly, minimizing sticking and jamming.Oil and chemical resistance

PTFE is chemically inert, protecting the metal substrate from oil, lubricants, or mild chemical corrosion. Shenzhen Hongcheng vibratory feeders maintain long-term performance without rust or contamination.Durable and wear-resistant

Enhanced PTFE formulations increase hardness and abrasion resistance. Feeder surfaces remain intact even under high-frequency vibration and constant part friction, extending service life.Protecting part surfaces

For precision metal, plastic, or rubber parts, PTFE coating reduces scratches and wear, preserving appearance and function.

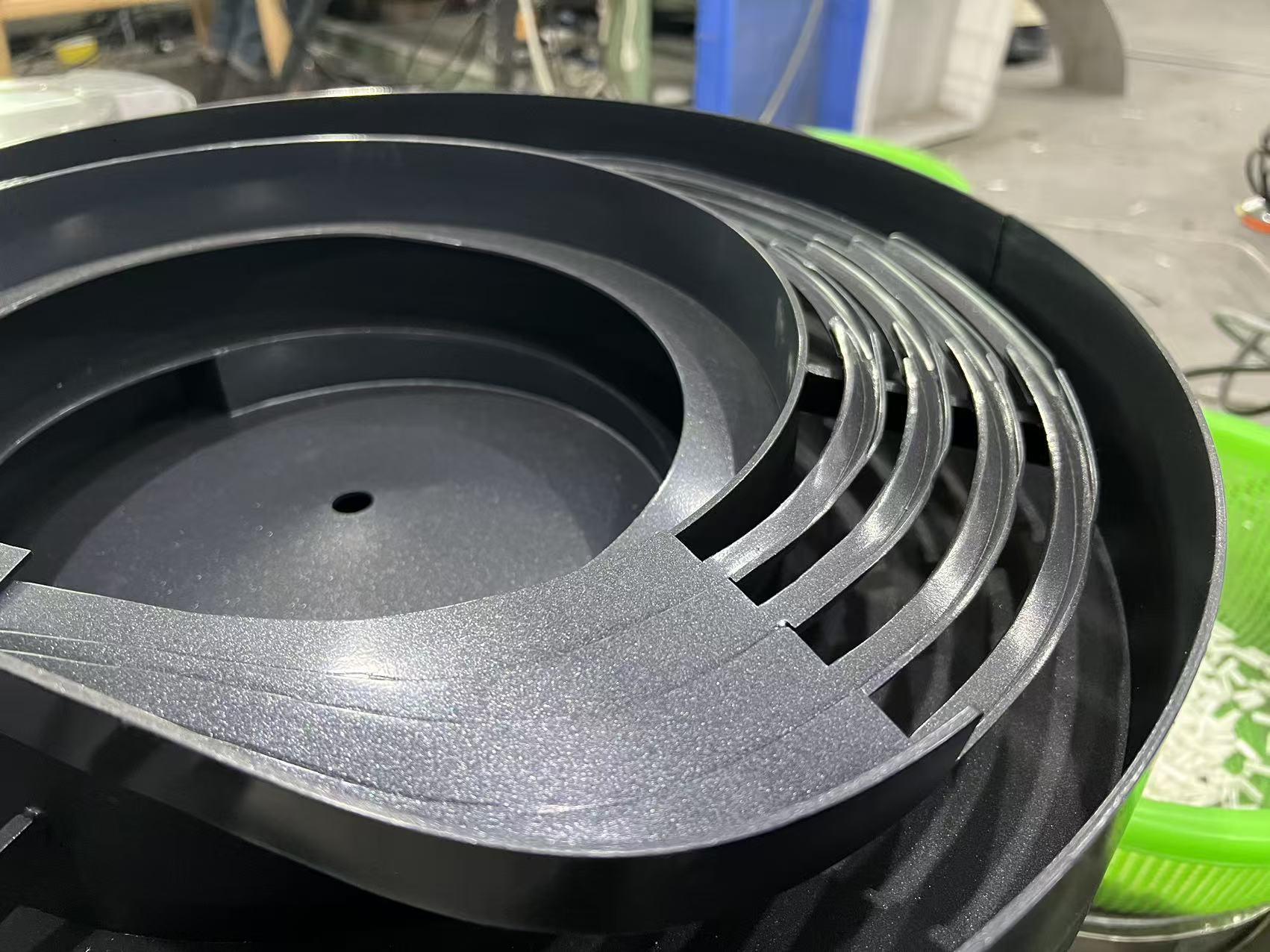

Professional Coating Process

Shenzhen Hongcheng strictly controls the PTFE coating process on its vibratory feeders, from substrate preparation to final curing:

Substrate preparation: degreasing and sandblasting to improve adhesion

Precision coating: uniform application of PTFE dispersion or powder

High-temperature curing: controlled temperature and time to form a dense, durable layer

Strict quality inspection: thickness measurement, adhesion tests, microporosity checks ensure every vibratory feeder is delivered with flawless coating

This comprehensive process ensures each vibratory feeder runs smoothly and reliably, even with challenging parts.

Application Cases

Hardware industry: screws and bearings feed smoothly, reducing jams by 80% and increasing throughput

Rubber components: O-ring feeding without sticking, saving cleaning time

Plastic parts: precise injection-molded parts maintain surface integrity, improving yield

With PTFE coating, Shenzhen Hongcheng vibratory feeders not only solve sticking and wear problems but also enhance overall production efficiency and reliability.

Looking Forward

Shenzhen Hongcheng will continue optimizing vibratory feeders and PTFE coating technology, exploring more efficient and eco-friendly coating solutions. Our goal is to ensure every vibratory feeder achieves smooth, reliable, and precise material feeding, creating exceptional value for our customers.